-

Posts

428 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by gbclive

-

-

Now straight forward to pass by on the towpath side.

However, the bulk of the tree remains jutting out from the offside.

-

The first two boats have just squeezed past the tree and the contractors or still beavering away in the rain and failing light.

So hats off to them and it’s looking good for tomorrow.

-

1 hour ago, ditchcrawler said:

Its a big tree from the photos I have seen, Photo by Mr. Lane

No sign of the Calvary yet.

I spoke to CRT - apparently no notice required yet “as the contractors will arrive on site to sort it within 4 hours”.

I fear this one might be the first of many over Friday, Saturday and Sunday.

My guess is that the issue is the sodden ground and this one simply fell over in relatively benign conditions.

Update… the contractors are on site and work is in progress.

However, it’s a big job.

-

Fallen Tree blocking the Coventry about 1 mile past Streethay Wharf towards Fradley Junction.

Or 0.2 miles SW of Brookhay Bridge

Apparently CRT aware but nothing notified yet I believe.

The locals guesstimate (hope) it might be open later this afternoon or this evening 🤞.

Il’l try to remember to update any developments.

-

1 hour ago, IanD said:

Does WaterNav offer something that opencanalmap (which seems to work quite well) doesn't?

I think the big difference is that WaterNav can be downloaded in advance with necessary data and thus works offline, whereas I believe opencanalmap requires an internet connection to work? But I may have got that wrong😏.

-

Thanks for the info Arthur. The iPad version seems to still be at v 1.6.4 from 7 months ago.

-

If it gets really hot, I cut out pieces of foil type of emergency blankets and stick them to the inside of windows facing the sun with bits of electrical tape. It’s a bit of a faff, but the foil is cheap as chips and translucent enough to still be able to see out, although it’s like wearing sunglasses in doors, so not good in the evenings etc.

My understanding of why this works so well is because of the greenhouse effect whereby the incoming short wavelengths of visible sunlight pass through the glass which is transparent to it. This heats up objects inside the boat (or car, or house). These objects then re-radiate longer wavelengths of infrared heat which glass is somewhat opaque to, so the heat is trapped inside. I use the foil gold side out which reflects enough the incoming radiation to make a significant difference.

Example of the foil, £10 for:

Bramble - 10 Large Multi-Purpose Insulated Foil Emergency Blankets Individually Packed - 210 x 160cm

-

3

3

-

-

An update on the shoal 0.5 miles north of Stafford Boat Club on the Staffs & Worcester. Ie between bridges 96 & 98.

I passed the area this morning and had a brief chat with the team who had just finished dredging. Apparently, there was some oil contamination in a sample from the outfall on the off-side, that was the source of the silt. Perhaps that was the reason for the considerable delay in dredging? Also, I never saw any nav notice, did I miss one?

Anyway, I hope this is good news, especially for any deep drafted boats.

-

2

2

-

-

1 hour ago, Turbobert said:

Interesting. I reloaded the app but no joy. My software is up to date too. I’ll look into the CRT reworked version. Thanks

Sorry, I’ve edited my reply to correct the reference I made to CRT, should have been RCR.

As you know, the original app stopped working a number of years ago after an IOS update and the app icons are very similar.

A slightly different shade of blue and a slightly larger W on the newer version.

It took RCR about a year to re-write the code and then some further time to debug, but they do seem to react to issues that are reported.

-

I’ve just checked on my iPad Air 2 with IOS 15.7.3, which is up to date, and WaterNav v 1.6.3.

Seems to be working fine.

Personally, I’ve found the the reworked version by RCR to be pretty reliable.

-

2 hours ago, magnetman said:

This is interesting. How did the boatyard know what was on the boat? Did they just ask the owner or attempt to gain entry into the internal spaces?

I don't think I would be all that happy with someone else (other than family members and the bs man) gaining entry to the internal spaces of my boats.

if the boat was in for dry docking I don't really understand how the yard would have become aware of what type of batteries were on the boat unless the owner told them.

In which case surely it is better just not to mention it. The boat isn't going to blow up because of having some lithium batteries on board.

Perhaps they have a disclaimer where you tick a box saying "no lithium batteries" and the owner in this case didn't tick the box.

It does sound a little bit like one of those stories one hears of.

“A friend 😏” asked Knox-Johnson specifically about LiFeO4 chemistry batteries. The underwriters confirmed no issue as long as it was professionally installed. I suspect some / most so called professional installers would be unwilling to get involved with a hybrid system unless a B to B charger was installed between the LA and the lithium. This of course adds significantly to the cost and complexity of the install. Note that the policy docs do not specifically mention battery chemistry.

-

4 hours ago, rusty69 said:

That's interesting. I can't see that information on their website. Do you need to ask them directly?

Also you say "if you change them". Is it possible for the user to change the settings on the fogstar and lifebatteries BMS or is it a password protected option only available to the seller?

OK, a little more digging and a little more info.

This YouTube video at 8min 25sec mentions the voiding note that comes up when opening the FrogStar app.

However, I did find a post in the “12 volt boating group” forum on Facebook, that suggested Frogstar might give the OK if the installation sparky contacts them before hand to explain the proposed settings and the reason for.

There is no doubt that Frogstar are aggressively undercutting the UK market, but they have only recently expanded the range to include LiFePO4 Leisure Batteries. Life Batteries have an establish record of supporting Hybrid installations.

So… I think that before buying from FrogStar, it would be best to contact them by email for their current position and file the reply as a record.

My instinct is to use Life Batteries, but FrogStar are considerably cheaper, so I’ll keep an open mind.

-

I’ve been considering going hybrid for some time.

The impression I have is that Mark at Life Batteries is supportive of the hybrid system and will actually help in setting up the BMS depending on your particular situation and your preference for how much of the capacity you want to utilise. He is also known for standing behind the warrantee, even when someone has done something daft.

On the other hand, Frogstar, who also have a good reputation, unfortunately state that their 10 year warranty will be invalidated if you change any of the BMS settings.

So I plan to go with Life batteries to supply a 12v 200AH Bluetooth LiFePO4.Not the cheapest, but overall seems the best choice to me for a hybrid system.

-

If you use pins which have a metal loop near the head, use a spare long pin as a leaver.

Insert say a 1/3 of its length through the loop, then with its pointy end braced against the ground, pull repeatably up sharply up on the other end using it as a lever. This gives a mechanical advantage and gets the extraction started so it’s usually easy from there. The longer the pin, the greater the potential leverage that is available.

Another benefit of this method is that it’s a very quiet way compared to using a mallet when trying to do a stealthy early morning departure without disturbing any neighbours😏.If stealth is not a factor, tapping the head of the pin in various directions prior to levering out usually makes things even easier.

One point of caution, heads of pins can become very sharp over time from hammering.

edit - sorry Cheshire Cat beat me to it and was much more succinct😏.

-

2 hours ago, Alan de Enfield said:

Yes I often had to do the same - the Gliding club phone number is impressed into my DNA

"Buckminster 385"

Ditto “Herriard 270”, Lasham clubhouse, also in the ‘70’s🙂

-

1

1

-

-

I used Roger Downer back in March 2017. Duke is a 1997 trad with a Kelvin.

He was very practical and helpful and I’d have used him again if we were still at Pyford.

-

Thanks for the useful information in various posts.

I’d noticed that this seasons SuperTherm had deteriorated drastically in terms of ash compared with my recollection from last winter, so It’s good to understand why - it is on the approved list.

-

23 minutes ago, BEngo said:23 minutes ago, BEngo said:

If Dick is too busy, send or bring it to Somerset and I will happily turn the end off for you.

N

Thanks, thats very kind of you.I’ve left a message on Dick’s answer machine.

-

1 hour ago, john.k said:

I was wondering from the pic if the pump may have originally had greased leather washers in the location,in the interests of economy...............as most will know ,the woven square section packing is not cheap,and leather would have appealed ............on ocassion ,Ive found square cut fur felt ,saturated in grease,also make a servicable seal for a waterpump.,and also the combination of felt and leather washers ,well greased.

That interesting. Duke is not that old, built 1993 with a 1948 J2. When I purchased the boat, the engine was getting warmer than it should on rivers etc. Kelvin engineers RW Davis investigated and identified the large but very poorly designed skin tank under the floor as the culprit. They welded a much smaller but properly baffled one externally on the aft swim. It was subsequently discovered that the original skin tank was clogged up with three bucket loads of thick grease! -

2 hours ago, BEngo said:

The top of the pump body has been chamfered, presumably because the top threads were damaged. That means you have lost the equivalent number of threads engagement before you start.

I think your idea of taking 6 mm or so off the gland follower is the way to go. The other possibility is to fit a sleeve as suggested by john.k. That seems like a lot more work. A new gland follower is fairly easy to make if you ever wanted to go back to original set up. You need a fairly big chunk of brass though!⁸

I find that water pump packing either lasts about a year, or for about 5 years. I can find neither rhyme nor reason to this. I have never managed to get more than two turns of packing in. That said, a litre a day is not a terrible consumption rate for an open ram gland packed pump. I tend to think I need to do something when it gets to about 2 l a day.

For john.k. The later, double acting water pump was a better design. Unfortunately it has leather washers which are hard to come by.

N

Thanks BEngo. I’ll phone Dick Goble to see if he would like to turn down the lower surface of the gland.Your comments on leak rates and number of packing rings are reassuring - thanks.

-

10 hours ago, dmr said:

Lovely photos, we see a lot of crap photos on this forum so its lovely to see some good ones.

We have a beta JD3 but I have been lucky enough to briefly drive two boats with Kelvins.

I realise this post is of no help 😀

Thanks dmr. I did not have the required gizmo to transfer files from my camera to my iPad, so made do with using the iPad’s camera. The in situ one was lit by my head torch. The black backgrounds ones were taken on a spare micro fibre cloth to reduce reflections. Their usual purpose is to mop out the sump during oil changes😏

10 hours ago, john.k said:Looking back at this....the packing gland is also a crosshead bearing for the piston...and too short already..........the whole mechanism is a crap design........I used to get stuff like this to modify so it works properly ,and it makes you wonder why the manufacturer didnt do this at the factory...............another product where the customers were the test engineers,and had to pay for the privilege.

But I still love my J2🙂 -

10 hours ago, john.k said:

Certainly,alter the gland to fit properly-...at least five turns of thread engagement.......there should not be any water in the threads,the packing should exclude all water from the OD,and only a few drops to lube the piston ...I can see where someone has ground out damaged threads,further reducing engagement...........if threads barely engaged are continually stripped ,youll end up with no thread left...........however ,its quite easy to build up bronze housings and re machine them,or to braze in an insert .......Do be careful with bronze tho,its got a very sudden melting point ,and flows like water..............I would have said at one time to pack up the casting with wet asbestos ,just in case,.......but now

-

9 hours ago, john.k said:

Certainly,alter the gland to fit properly-...at least five turns of thread engagement.......there should not be any water in the threads,the packing should exclude all water from the OD,and only a few drops to lube the piston ...I can see where someone has ground out damaged threads,further reducing engagement...........if threads barely engaged are continually stripped ,youll end up with no thread left...........however ,its quite easy to build up bronze housings and re machine them,or to braze in an insert .......Do be careful with bronze tho,its got a very sudden melting point ,and flows like water..............I would have said at one time to pack up the casting with wet asbestos ,just in case,.......but now I wont.

Thanks John. I usually find simple trumps complicated, so I’ll probably have the gland adjusted. -

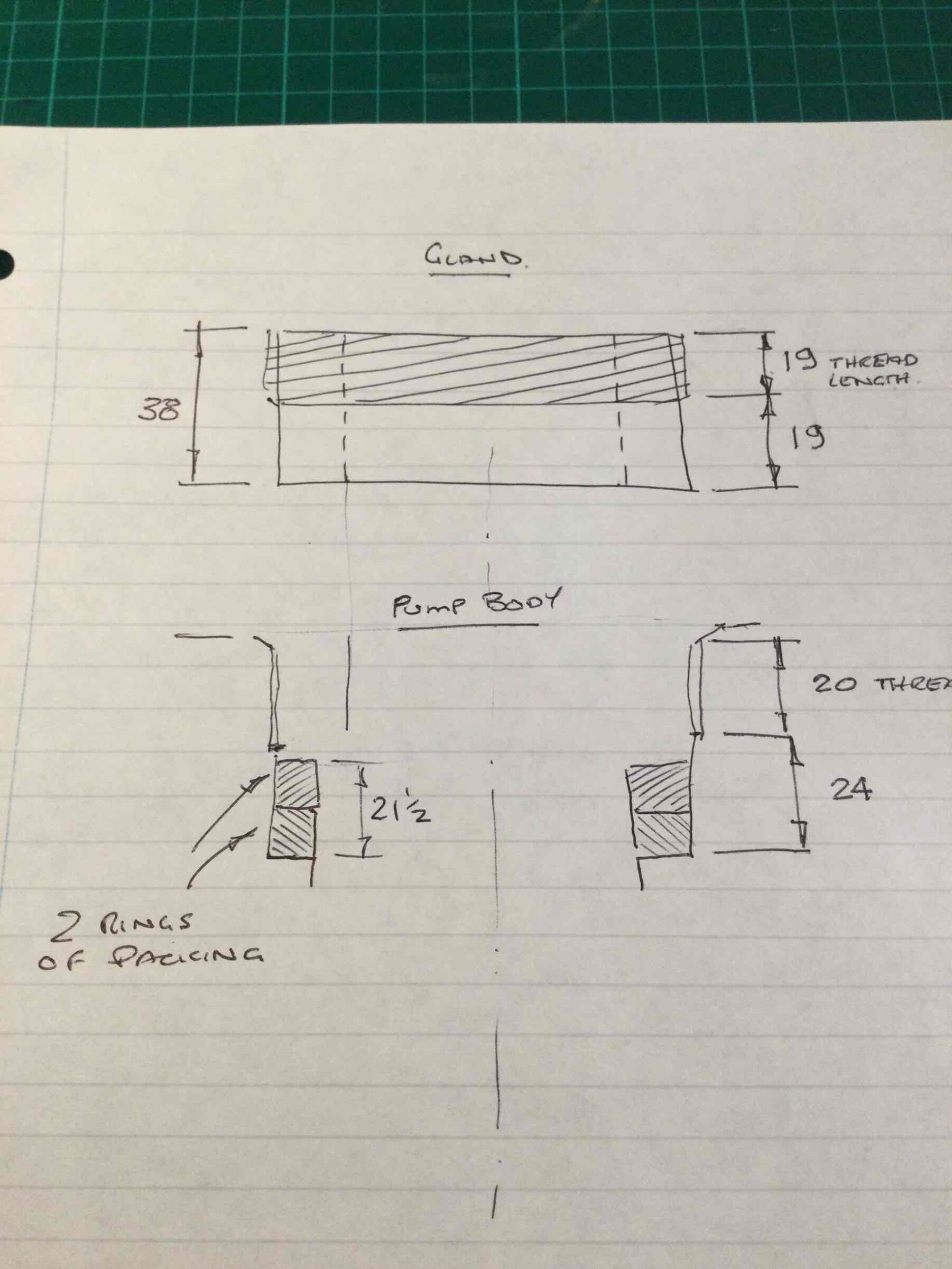

If I may, I’d like to resurrect this 2 year old thread in order to seek further advice. Long story short… the coolant pump body on my J2 was modified by a previous owner, reasons unknown. This has resulted in there being room for only 2 rings of 3/8” or 10mm packing.

My previous experiment with a hydraulic seal + 1 ring of packing seemed to cause more aggressive wear to the chromed ram than conventional packing. So 2 years ago I reverted to using 2 rings of conventional packing. This gave 1 year, about 1000h, of acceptable leakage, but steady deterioration over the last season with about 100ml per hour in spite of regular nipping up of the gland.

So I’ve just replaced the packing again using the same product as last time, then carefully reassembled the pump as before, only to find that the max amount of gland thread that can engage into the pump body is a paltry 2/3 of a revolution before reaching the top packing ring. This is a bit less than I recall last time and is obviously unacceptable and results in significant weeping past the threads. So I’m back at square one and looking for reasons and solutions. The nominal 10mm sq packing seems a sensible size in relation to the cylinder and ram diameters. 9.9mm gap and about 10.6mm actual size of packing.

First question please. I’ve attached some photos including the top of the pump body and a quick sketch. Can anyone enlighten me as to the previous modification and why it may have been necessary? I’m guessing that some bronze has been removed from around the top of the cylinder?

Second question. Would using a lathe to removing say 1/4” or so from the lower surface of the gland be something to consider in order to allow more of its threaded upper portion to engage with the top of the cylinder thread?

To my mind it would be bad form to do this kind of irreversible mod to a Kelvin component, but I’m working with a pump that’s already been altered in some way.

Thanks everyone.

Fallen Tree blocking the Coventry about 1 mile past Streethay Wharf towards Fradley Junction

in Stoppages

Posted

Agreed, a rare example of my expectations being exceeded 😊