-

Posts

1,648 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by Alastair

-

-

1 hour ago, Bacchus said:

Huffler 45/40? Very versatile boats...

We seriously contemplated buying one as a liveaboard.

Contacted peter nichols asking for basic info such as 'how do you lower and raise the mast?' Got a complete brush-off, they were not interested.

Two on the market that I know of. Selling for tuppence, compared to the build cost.

A nod from someone who has a friend who owned one said that they sailed like a dog.

Sad, because the concept is really good.

-

30 minutes ago, Flyboy said:

It is the wrong way up. look at the picture and you can clearly see the shroud on the trailing socket facing upwards which allows water into it. The trailing socket is always the larger diameter so fits over the plug so the socket should always point downwards. It sounds to me that you have got a surface socket (hollow pins) pointing downwards and a trailing plug (solid pins) inserted upwards. If you have a trailing plug both ends of the shoreline it's very dangerous as it's possible to touch the live pins when plugged into the shoreline. Please post a picture of you installation.

When I didn't know better, I fitted a surface 'socket' (the pin one) the wrong way up, just as pictured. The 'plug' on the cable filled up with water, just as Flyboy described.

-

30 minutes ago, Jen-in-Wellies said:

Annealing is a heat process to firstly heal the dislocations that have been pinned and hardened the metal, then recrystallise the metal,. then perhaps allow those new grains to grow, all of which takes increasing amounts time at temperature, measured in minutes, not seconds. The cool down rate from that temperature doesn't matter. I suspect that what most people do, heating to a dull red, then quenching isn't actually fully annealing the copper, but just slightly relieving some of the stress in it and it is still quite work hardened. Possibly a slow cool is allowing more surface oxidation, which makes a sheet harder to work? Could give the effect you see.

Quenching is another process that is used to effectively "freeze" a high temperature phase that has properties you want by reducing its temperature so rapidly that it doesn't get a chance to transform to the low temperature stable phase before there isn't enough heat energy left to make the change. Thickness and size of the object have an effect too. Pure copper, or Copper with some dissolved Oxygen doesn't have these sorts of phases at high temperature. It would depend what alloy your "copper" actually was if you saw an effect from quenching. Brasses do have lots of weird phases at higher zinc concentrations for example.

I don't know what material the copper in a copper banjo washer actually is. I'd suspect it would be pretty pure, but I don't know. A small washer is going to cool down through the first few hundred degrees rather quickly when removed from the flame, so all quenching is likely to do is make it cool enough to pick up straight away. Any metallurgical changes to the bulk of the washer are probably over by the time it gets to the water.

For the OP, probably the easiest thing to do is get some fresh new washers!

Jen

In the grand tradition of digressing from the OP, lets continue this post.

I did a bit of research to see if opinion had moved on from when I did copper work (and plumbing).

My research absolutely agrees with the part of your statement in italics.

Crystals form in copper as it is worked.

Heating to red heat randomizes the structure, breaking down the crystals. Fast quenching 'freezes' this state, just as you've said above.

Absolutely pure copper might behave differently, but the 'copper' that we have access to certainly requires annealing with a fast quench. Slow cooling after heating isn't as effective.

-

10 hours ago, Jen-in-Wellies said:

Not in copper. The change is taking place at the annealing temperature. Cooling rate afterwards makes no difference for any that can be reasonably performed. With a small thing like a banjo washer, cooling rate is going to be relatively high anyway. With some metals cooling rate is important. I also did metallurgy!

That contradicts everything I know about working with copper. Not a metallurgist, but i've done a bit of copper work.

We would soften work-hardened copper by heating then cooling rapidly. Allowing copper to cool slowly didn't reverse the work hardening.

-

1

1

-

-

9 minutes ago, TheBiscuits said:

I had my eye on the red handrail post ...

Yup.

If it had been me I would have had multiple ropes out - to the base of the railings, a hook on the pilings, a stake driven in and anything else - trees are good.

This is all a good reason to carry more rope than you normally need. Rope is relatively cheap!

-

Speaking from the point of view of someone who used to live on the Yorkshire Ouse, that isn't even a very strong flow.

The problem is simply people who have no idea how to moor in a current. There were loading of things they could have tied off to, including the bankside pilings.

-

I found that these fittings are far from rainproof and over time can fill with water.

If I used them again, i'd go over every seam in the plug and socket with silicone.

-

1

1

-

-

What Alan said, pretty much.

Most BSS examiners are quite aware that there is a subset of boaters who have poor appliances; they just take them out of the boat for the duration of the certificate. Presumably to avoid this, the examiner is wanting to make that dodgy practice a bit more difficult.

I think that fitting a end stop to each end of the gas pipework -something like this:

compression stop endWill be ok and satisfy the requirements. Also remove empty bottle (ask neighboring boat to store it if you can't just shove it in your car boot).

Be aware that these fittings should be made with copper olives (you have to buy those separately). Fitting just requires two spanners.

-

I'd suggest lighting a burner on the cooker first.

Then (leaving burner on) turn off gas valve. The gas in the line will burn off.

Once the burner has gone out, disconnect the gas cylinder.NOW you can undo the connections to the cooker.

If you don't do this, quite a bit of gas will leak when you disconnect the cooker. Not enough to be dangerous, but it will stink.

-

1

1

-

-

On 28/08/2020 at 14:45, Tony Brooks said:

I am not sure that I follow those diagrams. The stove and radiators need piping so the hot stove water will circulate by gravity for safely reasons and one calorifier coil can be put in series with that circuit or in parallel with the rads, depending upon where the calorifier and stove is situated.

I very much doubt you an run under floor heating on an un-pumped system but pumped circuits on stoves are best avoided. You could pipe the under-floor system as if it were one more radiator. That is in parallel with the other radiator and the calorifier but I doubt it would work when running on gravity.

The Webasto can use the same water as the stove so it could be in parallel with the stove but in summer it may lose heat via the stove. This very much depends upon where you fit the valve that you use to isolate the radiators and stove from the calorifier and that depends upon where everything is located in the boat.

That leaves the calorifier engaging coil on its own and no heat exchanger is required. Heat exchangers are sally required when you want to use waste engine heat to heat the rads because most engine runs their coolant at b6 to 16 psi and boat central heating systems are not normally pressurised.

how about a gravity system for the stove, and a motorised valve to shut this off from the webasto? The Webasto being on a parallel circuit to the stove, with the 'out' pipe from the webasto having a valve. Open valve when webasto is called for heat.

-

If you take the hat off, rain will run down the chimney and into the stove. What bothers you more, some tar stains on your roof, or rusted holes in your stove?

-

Quote

the current owner of this vessel is one of the marine industries best electricians

Interesting claim!

If at all true, I would expect a galvanic isolator or transformer, plus a well-fitted consumer unit.

The interior is better than the exterior.

Nothing wrong with overplating, if done well. Boats are welded together, so why should more welding be a problem?

-

1

1

-

-

2 hours ago, Victor Vectis said:

Yes.

I remember a conversation with a fellow member of our model engineering club. He was a Commander (E) RN rtd.

(I think we were looking at the engine in the Waverley at the time, as were Tim 'n' Pru)

He talked about a paddle steamer, it might have been a tug, capsizing when the paddle wheels were put into contrarotation.

Oh, OK, I can imagine that happening if done at speed or with high revs.

Sounds like operator error though; you can capsize a perfectly sound powerboat by turning it too tight through its own wake. Not design problem, operator error.

-

If you think you are getting plenty of opinions, just start a thread asking for advice about toilets . . .

Other people have covered most of the suggestions I'd give about looking for damage.

Waterline is a place prone to corrosion if the boat hasn't been looked after. Corrosion pits are usually rough and can be quite deep - if the hull sides were, say, 7mm thick originally, then pits of up to 2mm are absolutely fine. Deeper than that, not so good.

Also look at any 'through hulls'. Drain holes for sink, shower, engine cooling. All of these are places where corrosion can cause a lot of damage.

-

1 hour ago, MarkH2159 said:

Waverley is a seriously difficult beast to handle.

An inability to oppose the paddle wheels makes for an interesting and speedy approach being the norm to keep water flow on the rudder.

However, having almost 100% stern power is a bonus, but looks like it was not quite enough on this occasion.

Oh, that makes sense. What a shame that it is built like that, loses key advantage of a paddle steamer!

-

I suspect that the fancy compressed air toilet is broken (note; the more complex a system, the more likely it is to break). The porta-potti is a giveaway. Replacing or fixing that could work out to be expensive.

Check waterline for pitting and rust.

Check engine bay for rust, particularly around stern tube.

If that is ok, go for a survey.

-

I installed a godin in a house, about 20 years ago. Wonderful stove, particularly good when burning wood. Top-loading and tall meant that longish logs could be fed, rather than the stupid small chunks that fit in most stoves.

Mica is also terrific. Far more damage resistant than glass (since it will flex a bit). An impact that will shatter glass just damages one layer of mica.

When burning properly and with decent draw, no smoke should come out of the top when you load it. Ensure that the bottom vent is closed (replace the rope to ensure a seal. that way, when you open the top, the fire draws air in via the top instead of emitting smoke.

-

1

1

-

-

46 minutes ago, Bee said:

Just out of interest do surveyors crawl under the boat and test the thickness of the bottom? Its probably damn nearly impossible in some places yet that is a very big area of old steel.

In my experience, yes they do.

-

I would go for rigid - much easier to fit to some sort of frame so you can move them to point directly at the sun.

-

I had a 50ft dutch boat with ship's windows. Bloody heavy things (I bought two more to fit to another boat). Lovely bronze frames, glass about 30mm thick.

Secure as you like, plus they opened to let the breeze through (or to let you lean out and feed the ducks/swans).

Loved that boat.

-

1

1

-

-

What Tracy said.

If the accumulator was working you would get this pattern:

Open tap - water flows. After a delay, pump runs. If tap is only opened slightly, pump will cut out after a short run and water continues to flow.

If you open the tap fully, water flows, pump comes on after shorter delay and continues briefly after you turn tap off.

-

I won't comment on price.

However, you say you want to make it more 'open plan, removing cupboards...'.

Before you do that, I suggest that you pack up everything you need for a few weeks aboard (I'm guess you aren't intending to live aboard). Clothes, food, tools, bedding, towels, toilet paper, cleaning stuff; everything you would want. Everything.

Now put it all away in the boat. If there is spare storage, then think about removing it.

-

4

4

-

-

the bit below the compression fittings; is that a sort of filter?

If so, I'm very concerned about how close this is to the surface. When moving, there will be a lot of turbulence around this area. You only need a little bit of air sucked into that pipe and the pump can fail to draw. There will then be a cascade of problems; water not being sucked up, impeller running dry, then engine overheating.I agree with the people who say that your through-hull hole needs a proper fitting. For now, I'd suggest filling around the hose with silicone.

-

1

1

-

-

9 hours ago, Maanki said:

I stayed with the chap who first described this organism in the 80's when I was on a study trip to Australia (I'm an infection control nurse). Microbiologist called Rod Carter who worked in the Adelaide Children's hospital. He was examining a cerebrospinal fluid specimen from a child with meningitis down a microscope when something 'swam' across his view. Previously they cultured the CSF and of course no bacteria grew, so they kept getting cases of fatal meningitis that didn;t respond to the antibiotics you would usually use. He named it it Naegleria fowleri after his boss (smart move) then spent the next few years occasionally travelling the world lecturing on it. The good news is that it's easily cured with an antibiotic active against anaerobic bacteria called Metronidazole that you may also get for tooth abscess. Endemic in stagnant water holes in Aus, but everyone knows about it now. So not a brain eater.

That is a change. Back when this hit the news in Australia, they stated that there wasn't an effective treatment (early 80s).

Sudden huge shift in general swimming habits. Favoured waterholes closed, people stopped diving in, everyone went to the beach instead.

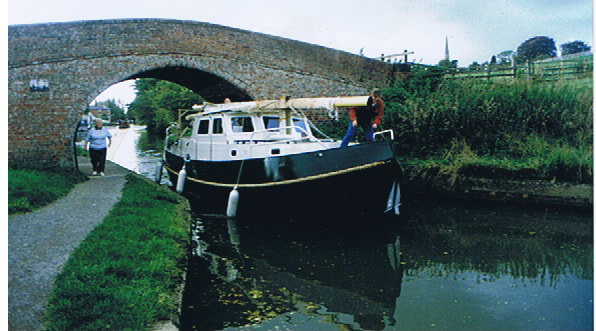

sealine flybridge on the grand union!

in General Boating

Posted

As far as I can tell, the sellers paid something like 250k for that boat.