hector

Member-

Posts

39 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by hector

-

Mikuni boiler has persistently smoky exhaust on start-up and stop.

hector replied to hector's topic in Boat Equipment

thanks both. I've just filled up the tank, so trying purely white diesel will require some faff... having done some research though, it seems like the usual place I buy fuel should be supplying ultra low sulphur red diesel, not heating/seagoing oil? Will investigate the pump as well... Cheers, H. -

thanks all, good to know that there's still some value there even if we decide to get rid

-

OK this is interesting... We have a Barrus Shire engine but I have some checking to do as I don't think I am used to the engine being anywhere near 1400rpm unless trying to perform some kind of emergency stop. Maybe the only fault with the unit is user timidity! Anyway - would still like advice on removal as like I said, not sure if we really want it on board either way. @JoeC thanks for the thoughts, that's a hopeful start.

-

We have an electrolux 3.5kw powerpack on our boat that was there when we bought, but has never worked properly (it gets going for about five minutes then just turns itself off). I am not really interested in putting effort into repairing it as we have never felt the need for it, and I also suspect it is unsafe as I have on one occasion received a nasty shock from its alternator. The question is - can I just rip it out, and simply remove its dedicated alternator and belt from the drive wheels? Or is that going to cause some kind of imbalance to the system that will affect the engine? Do I need to think holistically about the drag that the engine is expecting, having been set up with that third alternator in place? Ta, Hector.

-

Longer version... We have a Mikuni MX60 on board for rads and calorifier, and no matter what adjustments and tweaks are made, or which other things in the heating system crop up and are fixed, it continues to be the case that when it fires up, and when it goes through it's burn-off cycle when powering down, it belches light blue-grey smoke out of the exhaust. It has been serviced and had gaskets etc. replaced with not that many hours of use since. It's had coolant all checked and replenished after finding a leak in the system. The optical flame sensor was just checked and was clean as a whistle. It's had a kink in the fuel supply line, that might have starved it of fuel, sorted out. Although old, it basically does it's job very well when it works, it just continues to be very smoky when turning on and off. Enough to be a genuine problem for us and neighbours, especially when used in the marina. The only other thing I've checked (but not replaced) is the glow plug, which was also clean (I mean, no visible soot or anything). The coil around it was matt grey, but I have no real idea if that's normal or not. I suppose I might have expected it to be shiny (!?). But it's not smoky throughout use anyway, so the plug obviously works once heated up... but it's the next thing on my list to try. Any other ideas welcome... it seems like these things are phased out now so we are on our own until something forces us to replace it.

-

Fuel still pooling on top of engine... next steps?

hector replied to hector's topic in Boat Building & Maintenance

Thanks Tony. That washer wasn't obviously removable and so maybe any damage to it would require a complete replacement injector with this engine. Hopefully a proper test later in the summer will reveal more (or actually, hopefully not), but delighted that at the moment it doesn't look like anything's actually got a crack in it. -

Fuel still pooling on top of engine... next steps?

hector replied to hector's topic in Boat Building & Maintenance

Morning everyone. So first of all, thanks for the extremely helpful advice - I followed all these points through a complete disassembly of that injector from the fuel distributor to the injector itself, cleaned and inspected, carefully reassembled, and have just got myself the mile along the canal I needed to to get to safety - on first inspection when I moored up, there is now no fuel on top of the engine. Here's what I found out... 1. The injector itself was covered in brown diesel / liquid but which easily wiped off 2. The fuel supply pipe definitely isn't a nice tidy fit between both ends, it's not wildly out, but I'd say that if I did one end up first then it would be 1mm or so out of perfect alignment at the other end. Actually, applying slight pressure in the middle of the pipe made it sit much more nicely so I did that before dropping the nut onto the thread. Possible the pipe has been bent at some point and that is one of the issues. 3. I'm not sure where the soft copper washer is supposed to be, but there wasn't one underneath the injector clamp. However there doesn't appear to be one under any of the injector clamps. There is a movable ring on the inside end of the injector (see third pic) but I'd say it's steel. 4. I see what you mean, Tony, about resettling the injector clamp. Tightening one side fully before the other puts it on the wonk, so I did these up again a couple of turns at a time, alternately, until tight. Useful skills from my drumming days to deploy here as it's the same approach required to evenly replace a skin. Anyway, I'm away for a week now so just glad to have the boat where it was supposed to be, and currently no fuel leak fantastic so thanks all. I'll be able to put through more paces when back. Cheers, Hector. -

Fuel still pooling on top of engine... next steps?

hector replied to hector's topic in Boat Building & Maintenance

Amazing, thanks so much for your help everyone. Hopefully some updates in the morning! -

Fuel still pooling on top of engine... next steps?

hector replied to hector's topic in Boat Building & Maintenance

noted, thanks Tony! I'll check this first in the morning. Will a fractured/cracked pipe near the join with the injector will be fairly visibly obvious? Or could this be a microscopic crack that I may not be able to see? -

Fuel still pooling on top of engine... next steps?

hector replied to hector's topic in Boat Building & Maintenance

@ditchcrawler @magnetman OK, well that would figure as I didn't remember seeing an olive on the connection. It's possible in that case I could get them a little tighter, but I will also look into the possibility that the delivery pipe is fractured. If it is, then it's fractured inside where the union nut sits as there is no fuel anywhere along its run to the injector as far as I could tell. apologies, I see this is what you were suggesting anyway! -

Fuel still pooling on top of engine... next steps?

hector replied to hector's topic in Boat Building & Maintenance

it still doesn't sound right to me, although I haven't put it under load yet. -

Fuel still pooling on top of engine... next steps?

hector replied to hector's topic in Boat Building & Maintenance

but not.... overtight? so as to damage the olive, as mentioned above, I mean? I had been working on the assumption that that nut should be f-ing tight as you say, but have only ever operated it with a size 17 hand spanner, and wouldn't have thought I could have damaged it myself without use of something more heavy duty? -

Fuel still pooling on top of engine... next steps?

hector replied to hector's topic in Boat Building & Maintenance

Thanks all. I'll do some more checking in the a.m. to confirm for sure that it's not the main union nut, it just doesn't seem to be coming from there. but from underneath around the top of the injector. However a damaged olive from overtightening seems possible, and a build up of stuff caused by loose green nut also seems possible. I hadn't yet checked the jubilee clips on the rubber hose. Would a leak there result in the cylinder not firing properly or regularly if those are to return fuel? It was the engine sounding irregular and feeling sluggish that got me here in the first place. Anyway, I will follow these suggestions to readjust the clamp til level, and then remove the injector and see if there are obvious issues that tie in with your advice. And thanks @Tony Brooks I'll proceed with caution on removing the injector unless it just comes out... Thanks! -

Hi all, We've had what I thought was an intermittent problem of fuel pooling on top of our Barrus Shire engine around one of the 4 fuel supply lines to a cylinder - marked with blue arrow on the first pic. (sorry this post is probably going to be full of incorrect terminology...). Last summer we had this diagnosed as simply the threaded connection (red arrow in 2nd photo) not bedding properly, and that loosening it, re-bedding it and tightening up again would solve the problem, which we thought it had and all was good. We were then away over the winter. Everything's been fine since April, but I recently noticed fuel pooling again, which might have just started happening, or in all honesty could be just me not remembering to keep a look out. I never got a chance to properly clean the diesel puddle up from the under the engine. Anyway, today the engine seemed particularly sluggish and then suddenly cut out after about 10 mins under load. It started up again fine but definitely not firing smoothly so I had a closer look. Dried up the pooled fuel, carefully and firmly re-bedded the connection a couple of times to be sure, but gradually the fuel kept pooling. I am now fairly sure it is actually coming out under whatever the next stage of the connection is... the bracket type thing with the two bolts marked by the green arrows in the second pic. I checked those two bolts and one of them was actually quite loose, which surprised me, but I tightened it up (not tight hard as the rest across the engine seemed to have slight movement in them when a small ratchet spanner was applied). The fuel, unfortunately continued to gradually seep out underneath after the engine had been running a few mins. Any advice welcome. Should I loosen all three bolts (red and green) and remove the whole assembly to check for grime or bad seal or a blockage? Or will that loosen something inside the engine I'll wish I hadn't meddled with and I need to accept it's mechanic time? Many thanks for any thoughts to sleep on, Hector.

-

Thanks Tony, I'll head slowly up the canal. I've tracked down an available engineer a few miles away. I'll monitor the fuel and batteries, but yes I've often suspected the lights and alarm sometimes come on when we are heading out from being on shoreline for a while, and fully charged. We have no solar but the inverter was off so batts were reading 14.3 and not really any load on them. Maybe the fridge came back on! PS Yes, I've been on multi-issue threads on other forums... total nightmare, my original one was bad enough!

-

So... in the course of various investigations for the last question I asked, I now think there is a slow diesel drip under the engine which I only noticed (heard) after I switched the engine off, and I am fairly sure that... 1. It slowed to a stop as the engine cooled 2. That it *wasn't* coming from what the last thread identified as my fuel return pipe. It seemed to be coming from nearer the gearbox end, below the sump pump on my Barrus Shire 40 (04 build). However it's a trad stern boat with a compartmentalised bilge and so it's really difficult to see what's going on around the engine anywhere below half way down. Engine sounds a little farty and rhythmical out the exhaust to me, but I have been listening to it a lot, and just had the fuel cleaned so it's possible I am either just listening too hard or I have got used to the sound of dirty/wet fuel... If it's not the fuel return, what are some other problems? It's not pouring out, as there's only a few mm under the engine in a puddle to one side which I've only just properly noticed (it can often be damp down there, and only a torch revealed a pinky colour...) I'm about 5 miles out from our base marina with more skilled friends and mechanics, or a couple of miles from a usable mooring spot, so I suppose the other question is can I proceed up the canal with caution, or is there a possible cause of this that means I should definitely stay put? The engine is running, and doesn't seem to be spluttering or smoky or overheating or anything else. One (only one) of the battery lights briefly came on and went off again earlier today. Irrelevant? Thanks, Hector.

-

Height of fuel pick up?/engine cutting out…

hector replied to hector's topic in Boat Building & Maintenance

Yeah I think this could have been a factor for sure. I need to stand on the same side as the take off point in order to change the filter and prime it, so I could have been sucking up fuel then, and then standing across from it, or levelling off, to leave the engine running. At the moment we seem to be running (only one cut out since, dropping to idle when mooring, and it restarted straight away)... however immediate investigations after led to another issue I'd better restart a new thread on 😕 Thanks for you help everyone! -

Height of fuel pick up?/engine cutting out…

hector replied to hector's topic in Boat Building & Maintenance

I’ve definitely been looking at the feed - but if there’s a return that would make sense. I didn’t realise there would be a return (or a reason for one). Thanks! -

Height of fuel pick up?/engine cutting out…

hector replied to hector's topic in Boat Building & Maintenance

Yeah this was a first thought of mine too after having gunk stirred up… but I figured that would affect the filter priming process if it was jammed on the intake. I must have drawn a couple of litres through there over last couple of days. I’ve just put 60 L in and it seems to draw into the filter with the primer very easily. Engine not yet run long enough to know if problem gone though 😕 I have just done this, excellent idea! I’ve had another look and pretty sure there isn’t a lift pump. Fuel line seems to go from side of tank to the filter, then on a flexi hose to what I think is the throttle, then the distributor. something that I’ve taken for granted but someone pointed out is anomalous is that the feed to the heating is not on its own pipe from the tank, it branches off the same supply as the engine, between tank and filter (it has its own cartridge filter). I’ve currently got that line switched off on a stopcock though, as I figured it might be drawing rubbish or air backwards out of the heating system filter? weirdly, though, there is a second copper pipe coming out of the tank, which meets a flexi hose and then disappears under the engine… (but doesn’t seem to be hanging loose, I just can’t see where it goes). Any thoughts what this is? Would a diesel tank have an overflow outlet into the engine bilge? -

Height of fuel pick up?/engine cutting out…

hector replied to hector's topic in Boat Building & Maintenance

Thanks both - that’s interesting it was doing this below half tank… Our engine is a Barrus Shire 40. It’s a brand new filter, which I’ve since checked is seated properly and have bled that, and the injection points a few times. there’s no independent water trap just a drip point on the bottom of the filter. I’ll put 40L in in the morning and see where I get to if I bleed and prime the whole thing again. in terms of fuel pumps what am I looking for? Bit of a novice with engine stuff. I don’t think there is a pump in the fuel line to the engine… but is there always one? The filter needs primed by hand on the filter header, and the engine needs turned over to check if the injection points are spitting (as opposed to just having the ignition on… which I gather is sometimes the case). h. -

Hi everyone - we’ve been stuck with an engine cutting out after about half an hour yesterday and the day before (stationary boat, cuts out quicker under load). This is actually after having the fuel cleaned so assumed that we just had some crud kicked up into the pipes that needed worked through, or air trapped. the problems persisted through several attempts though, since Sunday afternoon. the fuel cleaners actually took about thirty litres of filthy fuel away though and I’ve been running the engine for a while… so it suddenly occurred to me to actually check the level. At first I thought it was fine as a good four inches left but after some further research it seems like the take up pipe could be that high? I had thought maybe an inch or two at most… so I guess the question is, have I solved the gunk/air in pipes issue and run out of fuel in the process 🫣 Thanks for any thoughts! h.

-

Hi everyone, well thanks for all this - the basic Q answered, but plenty more to think about I've had my eye on an all-in 200W kit from Renogy which afaik is 12v only, and I'll consult with them about if/where/when I need to be able to break the circuit. I agree that where that problem exists it seems like wilfully bad design, but I've bought plenty wilfully badly designed technology in the past. But the fact I can add panels onto the system without completely reconfiguring it is good news, I can proceed with caution. Cheers! H.

-

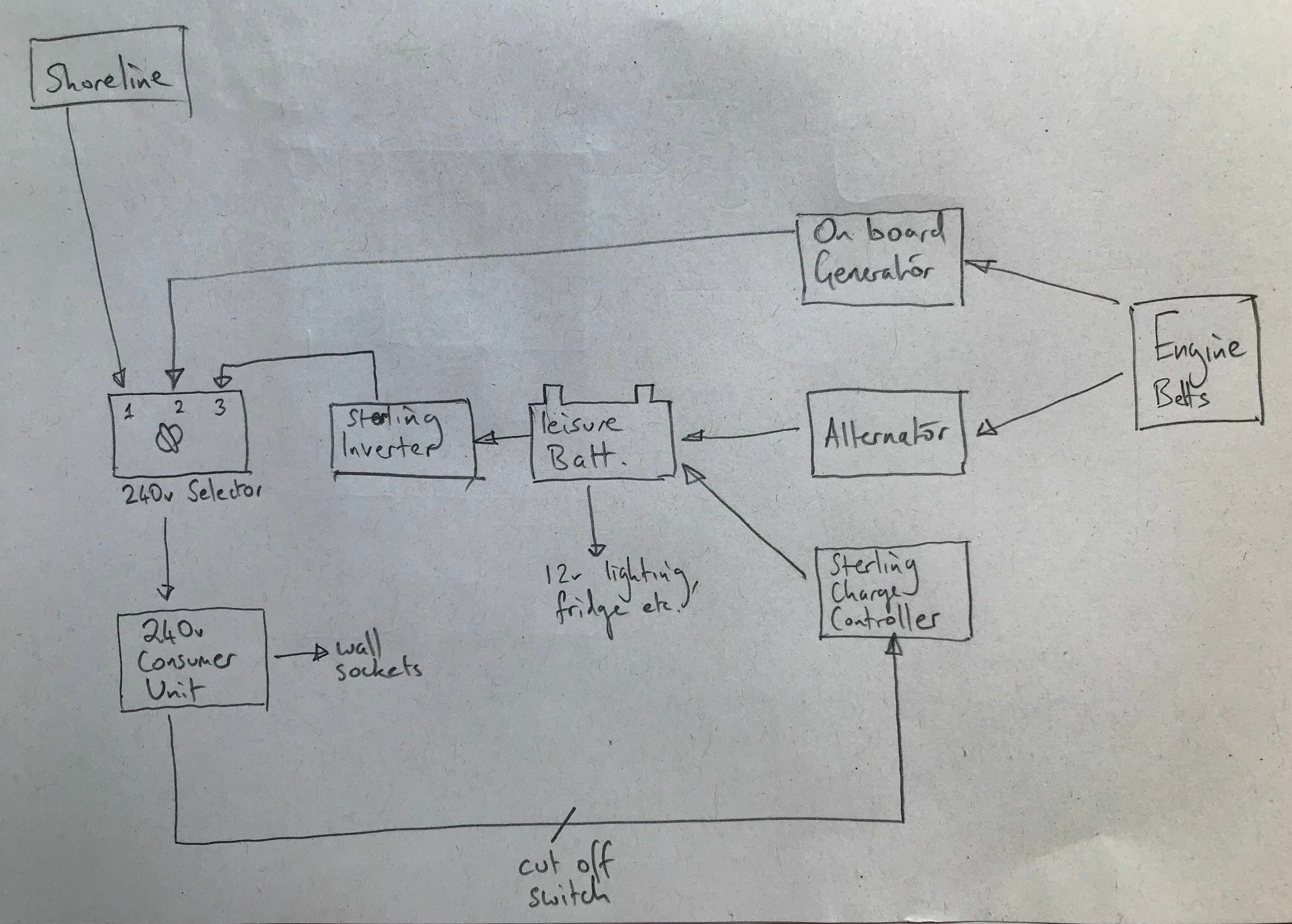

Hi everyone, I know this gets asked a lot, but the answer always seems to involve a certain amount of "every boat is a one-off" so I am asking again... Our narrowboat currently has no solar panels and I want to install a basic 1 or 2 panel kit, which will come with an MPPT, to keep the leisure batteries up. The starter battery has it's own alternator so I'm not planning on trying to have the solar charge it. My question is simply whether I can just connect the MPPT directly to the + and - of the first battery, with an appropriate fuse in line with the + (they are 12v batteries connected in parallel), or whether I have to worry about some more complicated integration with the shoreline charging controller (not an invertor combi) or charging from the alternator. So, I will have the alt, the charger, the MPPT and the batteries all wired in parallel, and in this case am I right in thinking they will all just 'see' the highest individual voltage and behave accordingly... so to speak. I have attached (I hope) to this post, a rough block diagram of the domestic power set-up as is. Many thanks, Hector.

-

Cheers Alec, that's v helpful!

-

Oh great! I actually have loads of those little pads lying around, I'll have them to hand in case the nylon turns into a faff.