monkeyhanger

-

Posts

747 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by monkeyhanger

-

-

2 hours ago, magnetman said:

There was a bloke a number of yars ago who had two matching narrow boats and welded them together with link bars. He registered it by length as a single craft but was able to separate them by cutting the welds off with an angel grinder. Each hull of the catamaran was in effect a powered narrow boat.

Don't know if he ever got found out but it was quite amusing.

That boat is for sale on the Duck at the moment. FYI, they are not welded together, but fastened using stout wooden beams. And he wasn't "Found out" as you put it. It was totally legal and BW were happy to licence it.

-

1

1

-

-

Has anyone experienced problems getting a boat through these locks recently? I saw a post on Facebook a couple of days ago, which appeared to show a converted Town class boat being towed backwards out of one of the locks. Unfortunately the captions didn't make the situation clear.

-

4 hours ago, SandyD said:

Hi all,

Out pumpout tank is Knackered and we want it out and replaced by a cassette. I have approached a couple of marinas (Braunston, Hillmorton, Calcutt) the soonest they could do this so far is June/July can any one reccomend somwhere else that might be able to do this work sooner? (we are based at Calcutt),

Sandy

Try Alvecote Marina. Speak to Lawrence. He may be able to help.

-

I've heard a rumour that there may be problems on the horizon for Cavalcade this year. I heard that the London Waterbus Company is refusing to give up its moorings on the south side of the pool for the duration of the festival, as they have done for each of the 20-odd years that I've been going. If this is true, it will cause all sorts of problems trying to accommodate all of the 120 or so boats due to turn up. Has anyone else heard this?

-

It should have a gasket.---if you can get one! Be VERY careful removing the side door and you may not damage it. I bought a roll of gasket paper and make all my own.

-

25 minutes ago, steve.sharratt said:

Cheers. I just got my oil delivery so good timing! I ordered 20 litres so should be good.

I converted mine from dry to wet sump, as I didn't have an oil tank. I just poured the oil through the opening created when I took the side door off until it was at an appropriate level. I had already made a dipstick, so I marked it at 1, 2 and 3 gallon levels for checking purposes. Initially I put in 3 gallons, but as I put a squirt of oil on the valve gear every day, I now fill to 2/12 gallons and the daily squirt from the oil can gradually tops up the sump.

33 minutes ago, steve.sharratt said:Cheers. I just got my oil delivery so good timing! I ordered 20 litres so should be good.

What oil are you using? I used to use Morris's, but I now have a paper oil filter in the sump so that I can use cheap ( well, not really, perhaps cheap-er) Halfords 20-50.

-

On 08/03/2023 at 18:23, steve.sharratt said:

Apologies for the slow response. I have a wet sump. I have ordered 20 litres and will see how I go.

I have a wet sump JP2. I put about 12 litres in.Make sure you don't put too much in so that the crank touches the oil.

-

On 05/03/2023 at 12:40, NarrowboatReliance said:

Hello, could you please clarify what you mean by 'big cover and the cam gear'? I'm intend to do a full oil change of my Lister JP2 marine engine soon and want to this right

The large plate on the starboard side of the engine. It sometimes has the decompressors in it. 8 brass domed nuts. The cam cover is the smaller one to the rear of it. You don't need to remove that one.

-

On 12/02/2023 at 21:32, matty40s said:

Where did.Ara end up?

I believe it's at Rothen's as well. From what I remember, it needs a lot of work on it,

-

17 hours ago, frangar said:

Why go higher?? I’d say that was bang on…what oil grade are you running at? The manual says 15-20psi when running so 18psi is good. What’s it doing at idle when warm? If it’s below 15psi then possibly it needs thinking about but even then I wouldn’t worry unless it’s below 10 psi. It’s very different tolerances to a modem engine.

I run it on Halfords 20-50, as I have converted it to wet sump and have an oil filter fitted.When the engine is really hot the pressure is probably around 10lb

-

My JP's oil pressure gauge reads 18lbs when warm and underway. I've got the water pump off at the moment, so access to my oil pump is easy. Is it worth turning the adjusting screw a bit to get the pressure up to 20lb? If so, do I screw it in or out, and by how much.? I should mention that the big end shells were replaced 3 years ago, and the main bearings 2 years before that.

-

On 22/10/2022 at 11:36, frangar said:

Thats a cracking idea! I shall give it a go

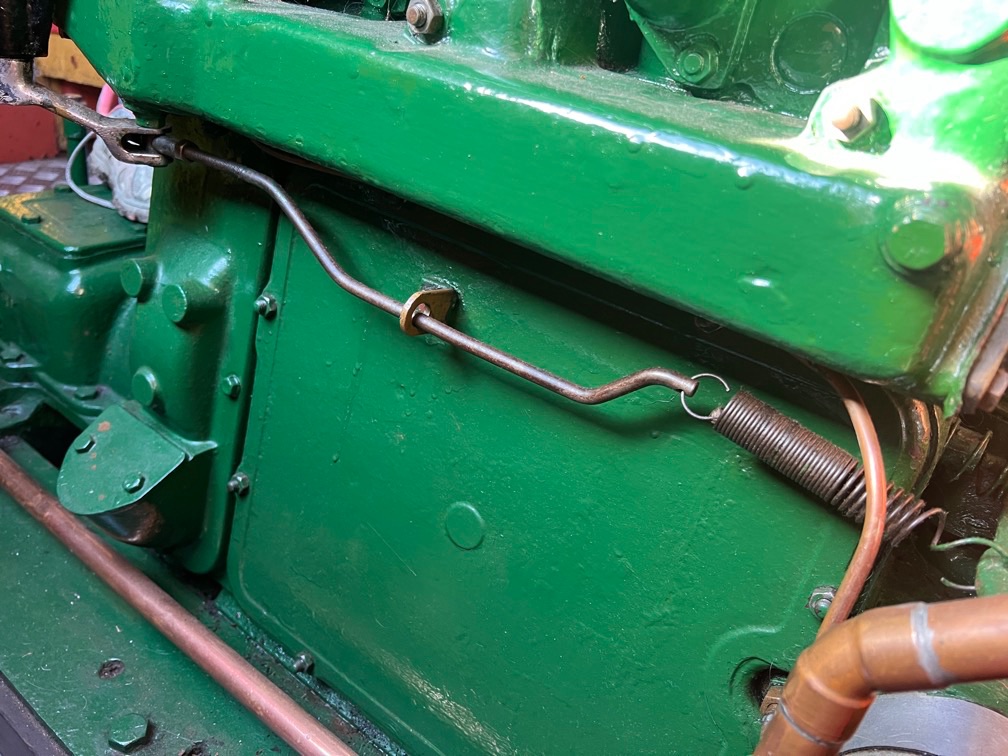

Mine has a dog leg in it as shown in the pic below as it allows it to go through a support on the side door. then back to the level of the crank lever...I think the holder is original but Im not sure if the rod is...the spacers on the end which goes to the vertical rod look very home made!

On my JP2 the throttle rod used to rub on the brass guide fastened to the crankcase door, and this had the effect of making the tickover very erratic. I changed the rod for a short length of chromed chain from B&Q, and hey presto! ...... nice steady idle.

-

57 minutes ago, Bob Chamberlain said:

Nothing to do with plumbing! For some weird reason all of the screws on my external fittings are rusty! I reckon whoever painted it last removed the originals (all 5mm metric machine screws) and replaced them with plain steel or at best zinc plated Posidrive countersunk (NOT galvanised). So, I've been working my way through removing them and replacing them with decent stainless countersunk Allen head screws. So far so good - and I'm managing to remove most of them without the heads rounding off. However, under one off the door hooks they obviously broke off the tap when threading the hole - re-drilled another hole adjacent to the first and broke the tap in that as well! There's not room to drill and tap another new hole under the hook plate.....! So I have two broken taps stuck in the bulkhead and only one screw holding the door hook. Any good ideas on how to remove the broken taps so that I can put new fixings in? Can't realistically apply heat because of burning off the paint etc. and because of how the tap is broken can't get a drill to start on it properly to drill it out.

Thanks!

I've managed to remove broken taps in the past by sliding a couple of nails down the flutes and twisting them back and forth with a pair of pliers so as to unscrew the tap. Take your time over it and you'll get there. Good luck.

-

1 minute ago, narrowboatmike said:

We are looking for narrowboat insurance for a 3 year old, 57ft,

owner fitout. Any recommendations would be greatly appreciated.

I've been with "Nautical Insurance" of Leigh on Sea for at least 15 years. I'd highly recommend them. They paid up within a couple of days when I bent my prop and needed a couple of drydockings to sort it.

-

54 minutes ago, Mad Harold said:

As a lad my dad and I used to have regular Saturday trips on the Humber paddle steamer ferries from Hull to New Holland and back.I think there were three of them.Tattershall Castle, Lincoln Castle and can't remember the other.

In those days pubs used to close early afternoon, and the old man usually wanted to have another couple of pints and as the bar on the ferry was open all day that's were we went.

While he was in the bar I used to watch the huge piston rods moving back and forth and go on deck to listen to the slapping of the paddles.

Happy memories.😌

The other is "Wingfield Castle" which is moored in Hartlepool , where the three of them were built. She's awaiting restoration, which , sadly, seems a long time coming as she's laid there unloved for quite a few years now.

-

On 27/09/2022 at 17:01, Tony Brooks said:

I think that should be Marine 16 Shock Treatment, not the maintenance product.

That's the injector cleaner apparently

-

1

1

-

-

1 hour ago, monkeyhanger said:

That looks useful! Thanks for the info.

Well, I've ordered a window curtain cable, and I've spoken to a guy at Marine 16. He says that their Diesel Injector Cleaner will remove all harmful deposits from my fuel system WITHOUT having to dismantle it and physically clean it. However, now that my system is in bits anyway, I figure that I'll clear the pipes by hand first, use bleach on it, then add the injector cleaner when it's back up and running. Belt and Braces, eh? Thanks very much to all the people who have contributed with ideas and information. Hopefully what I'm doing will sort the problems I've had. I will endeavour to report back some time in the future (2023 cruising season) to let you know how it went. Thanks again, everyone!

-

26 minutes ago, ditchcrawler said:

That looks useful! Thanks for the info.

-

7 minutes ago, Tony Brooks said:

I think your idea stands the best chance of success as long as you can ensure you do not get an airlock in the pipe when you fill it. It may also help if you can do the flushing with an adaptor on a hose, so you get a bit of volume through the pipe.

Because of the way my system is designed, with a couple of air bleed points, air locks won't ( well shouldn't) be a problem. I may be able to borrow a "Pela" oil extractor which may help to do the job of flushing through.

1 minute ago, Peanut said:Do you have a piece of flex which will pass around the bends?

Sadly not. The bends in the final 6 inches are very tight.

-

16 hours ago, Tony Brooks said:

How long are these sections? To be honest I would be reluctant to try any sort of pull through in case it got stuck.

If you are willing to take that risk you might be able to push a length solid copper conductor (house cable) through the pipe and then twist the centre of a small piece of lint free cloth in the end to act as a pull through.

I have 2 short section of about 2 feet each, both of which are reasonably accessible, and I should be able to clean these two OK. However, the longest pipe is about 8 feet long, with a couple of sharp 90 degree bends where it approaches the CAV filter. This is the one which concerns me most. I can blow through the pipe quite easily, and I have pushed a length of 1.5 electrical cable along it, but it only goes as far as the bendy bit, which is, to be fair, only about six inches from the end of the pipe. I haven't had the chance to flush it through yet, as I need a small funnel to help fill it. As I am typing this, I've had an idea! If I were to block the lower end, then fill it with a bleach solution, leave it overnight, say, then flush it through with water, then clean diesel, that might do the job. I still like the idea of being able to physically manually clean the pipe, but I fear it may not be possible. What do people think?

-

Just now, JamesFrance said:

If you dose the fuel with Marine16 it should remove any bug in the fuel lines after a day or two of running.

I regularly use Marine 16, and will continue doing so, but since at the moment I have access to both ends of the 3 sections of fuel line that I have, I was hoping to clean them out totally. If Marine 16 will do that (eventually) then great, but it would be nice to see them shiny clean before I put things back together.I was hoping that someone may know of a small bottle brush with a long shaft which may do the job. Perhaps as Tracy D'arth suggests, bleach is the answer.

-

I've had a problem with sludge in my day tank caused by diesel bug, and have removed the tank to clean it out. I've also disconnected my fuel lines and ascertained that they are not blocked, but there seems to be a fine layer of black something on the walls inside them. If I were to reassemble everything, I'm sure that there'd be no problem with getting the engine to run, but I'm concerned that, over time, whatever is inside the fuel lines may eventually multiply and cause a blockage. Removing the fuel lines completely is not an option due to the way the system has been assembled. Does anyone have a suggestion as to something I could run through the fuel lines to clean them out fully, please?

-

On 16/05/2022 at 13:23, Maudesmaster said:

Ok after guesstimating a 21 x18 pitch a new propeller was purchased and boat launched September last year so 6 months trial (couple of short stays in Cowroast to have sprayer pump and sprayers reconditioned)

The boat very slow to uptake and tickover slight above walking pace of a Three toed sloth and 3/4 revs between 2 mile posts taking 25 minutes ( rough calculation 2.4mph) Prop was removed last week and taken to T Norris to have a further 3” pitch

Watch this space for next thrilling instalment

thank you all for your input though much appreciated

I have aJP2 in my boat. When I had the boat built I specified a 25 x 19 prop, as recommended by a well known Lister guru. In use the boat always felt very slow and underpropped, so at the first blacking,I took the prop to Norris's to ask their advice. I asked them what would be the maximum they could increase the pitch to. The answer was 25x23, but they would recommend 25x21. I had it repitched to 25x23, which makes for relaxed cruising but stopping is not great, and the boat can slew across the cut under hard braking if I'm not careful.

The moral.....listen to Norris's advice, and try not to have more pitch than you really need.

-

2

2

-

-

3 hours ago, monkeyhanger said:

What are the arrangements for the illuminated cruise, please? I'm struggling to find any details.

I saw your post on Facebook today, so I'm up to date with it. Thanks.

And my computer has just updated, so I can now see your more comprehensive post on here. Thanks again.

-

1

1

-

March of the Widebeams

in General Boating

Posted

20230205_141507.jpg Hope this works. Sorry it took a while. Not a good photo, but it's not easy to fit a boat of that size into a small phone!