Welcome. As a new owner you may find the following helpful.

Always top up with an anti freeze mixture.

Anti freeze has a life based on its anti corrosion additives, 2 to 5 years is typical. If your coolant is more like an oxtail soup you probably need to drain, flush and refill.

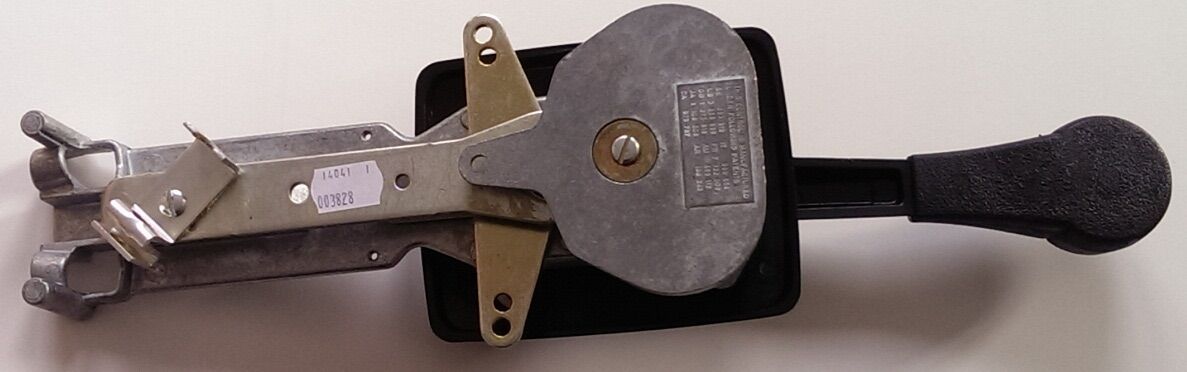

The small green wire, top left appears damaged. A piece of insulating tape will do as an emergency "bodge".

The cable clip immediately below the green wire should be attached to the engine, check the wiring for damage first before refitting it. This might also be a grounding point for the harness, others will be more familiar with it.

The black plastic item taking up most f the right hand side is the two piece cover for the infamous 11 way connector; well known for a variety of issues. Always worth checking when something odd happens with the electrics.

The smaller connector to the right is for wires 12 & 13; usually associated with the second (domestic) alternator.

The small black 2 pole "chocolate block" connector right at the bottom is evidence that the main 11 way harness has been altered or repaired in some way.