DanKim

New Member-

Posts

10 -

Joined

-

Last visited

Profile Information

-

Location

Stockholm

-

Occupation

Salesengineer

-

Boat Name

Damen

-

Boat Location

Nynäshamn

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

DanKim's Achievements

Gongoozler (1/12)

1

Reputation

-

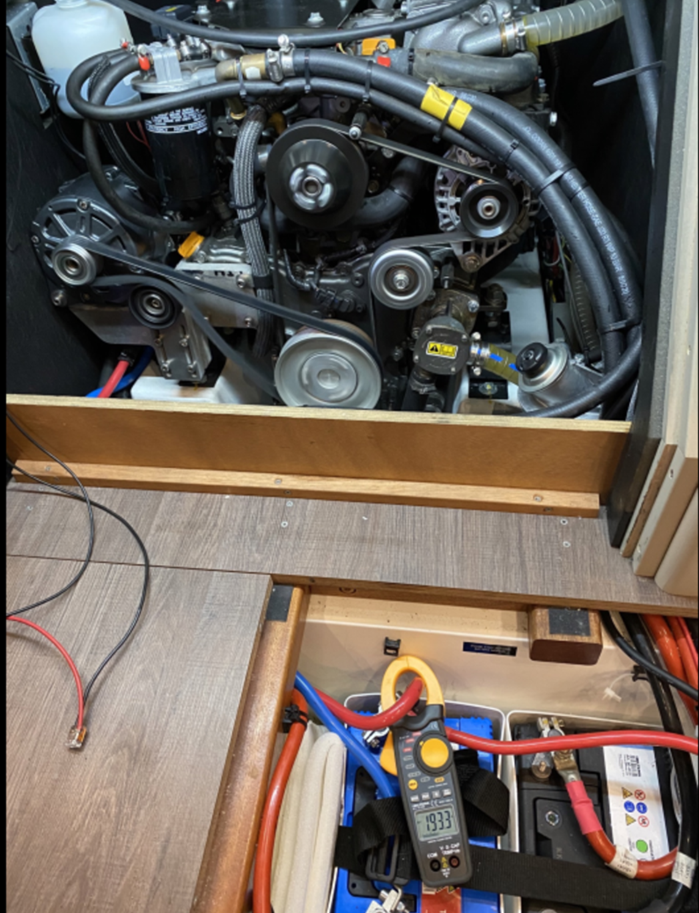

Hi gentlemen and ladies. Latest news from my project of a water cooled alternator. It’s a dream. I charge normally 225A continuously at 1400rpm and the temperature is 42C. When idling I charge100A att 680rpm. The idling is going down caused the load. I am stripping out everything in the alternator and only left the carbon brushes then it’s a generic alternator left. Two cables are connected directly to the brushes. The field is supply by a Balmar MC-618 and a shunt with blue tooth. Everything can be controlled over my smart phone. Also, a temp sensor is attached inside the alternator that give feedback to the Balmar regulator. 3 thick cables of 25 mm² is connected to the stator inside the alternator. They go further to an external rectifier of 300A that are also water cooled. Why don’t I use the internal rectifier? Its to week for this hi amp. I have burned so many rectifiers. The alternator is stamped with performance of 190A but that’s not for continues work. Very seldom a alternator can produce continuously what they are stamped especially at lower rpm. Why? The internal fan needs a high speed to cool down the internal heat. As we know is the efficiency only 50% this means a significant amount of heat must disappear somewhere. When I charge 225A at 14 volts, its 3000 watt of heat inside the alternator. To cool down this by air is not simple. Any disadvantage for this kind of solution? Need to understand everything how it works, not only about electronics also plumping! Spent so many hours to solve the circulation without having air in the system. Having air in the system could ruin the alternator. https://www.youtube.com/watch?v=9CrBNP1dqzs&t=2s

-

Hi Chris mail me on dan.kimblad[at]gmail[dot]com

-

The new alternator have a bigger wheel, the diameter are 63 the old one 49. Yes we add up a idler wheel for increase the wrap. But notice, Its one belt for each alternator. I doubt that will be any problem. The engine didnt complain at all 🙂 I forgot to measure the smaller alternator how many amp that one was pumping out.

-

I have tested the alternator. I have removed the internal regulator (snipping off al leads to the IC internely) and soldered two flying leads out that are connected directly to the carbon brushes. The leads are connected to at 0-30V 0-20Amp adjustable power supply. Idling at 800rpm and sourcing 12V to the field we got close to 200Amp. Will replace the air cooled alternator this winter by a water cooled, then we will have 400Amp charging.

-

I have change the ratio by 77% from the flywheel to the alternator from the original. today it is 178/49 (diameter at wheel in mm) The VDO taco are not correct after this rebuilding. But its simple to adjust it (my colleague are product manager for VDO Marine in Sweden 🙂 ). Idling at about 700rpm my 155amp charge 95 amp and at 900 rpm it charge 130 Amp and at 2000 rpm 135 amp. No idea to over run the engine. The amp curve are flating out at a certain point. In my case its about 900 rpm. When I start the engine it charge about 140 amp at idling and 195 amp at 1000 rpm and after five minutes its 95 amp resp 130 amp.

-

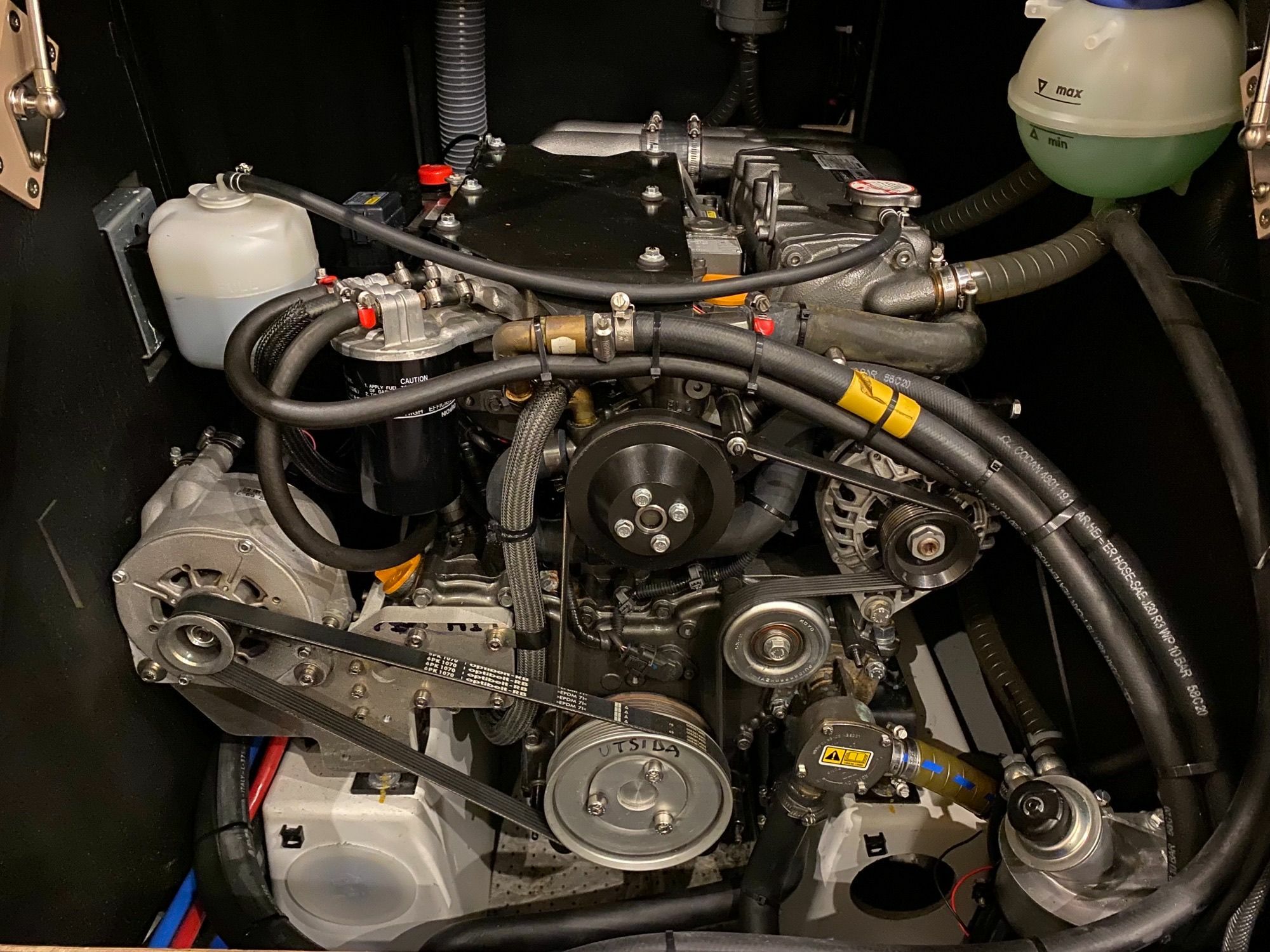

As you say a well designed regulator with full load download switch when you are maneuvers in narrow water to slow down the charging Amp are vise to have if you have a too small engine. Or have a switch for charging or propulsion by using a smaller engine. The alternator 059 903 015T from a used Phaeton has arrived (180€) I refurbished it last night and painted it in Yanmar grey. I am so impressed. It has 12 diod. A friend has this alternator in his towboat with a Balmar regulator. He charge 276Amp over one hour!!!!! Its the heat that are killing diodes and winding. By cooling it down thru a heat exchanger with seawater, it keeps the alternator cool. The rotor are air cooled by internal fan. By lower revolution there are limited flow of air. It could be that I add a external fan to have stream of cool air throw the alternator as I have today with the Renault alternator. The rotor are generating about 140 watt of heat. My older brother will have two alternators, it means it will charge 550 Amp. As little brother I will install those in his yacht. I will come back with picture when this are done. Wife are in Caiscais Portugal so I have free playtime and could bring in the toys to the dinner table from the work shop 🙂. Please, don`t tell her! Happy charging

-

Google on this alternator 059 903 015T This one are for Porsche/Audi/Bugatti/Toureg/Phaeton 190Amp and internal regulator. The belt are a multiribb 6. I ordered this alternator and i will get it tomorrow 🙂 It has internal regulator but it will improve al lot compared to what you have today if you use it as it is. Best thing are to have a external regulator. So far I think Wakespeed regulator WS500 are the best on the market. I have order one but have not get any confirmation when I will get it. It will be a huge strength on the belt and radial force on the water pump. Look on my earlier picture you can se that I have a singel belt only for the water pump. This belt will remain the motors whole life time. The tension on the belt are huge when the alternator are charging over 200 Amp. Effienciy are 50% this mean that you have about 5 horse power on this belt. The belt has to surround the wheel on the alternator by 180 degree otherwise it will slip. Attached picture, this week i have dismantled (removed the pcb board) the internal regulator and connected two wires to the carbon brushes. Those two flying leads will be connected to an external regulator later on. My intention are to build a own regulator. The regulators on the market today are compromises and not made only for LiFe I have being working with PM DC motors for 34 year and I am married with this topic. My new subject are alternators. The best thing I new is to improve things. Todays alternators are more then 50 year old. To improve this antic device is a goal for me. Happy charging :-Dan

-

Iti s running on its own system. Its heat exchanger only for the alternator. Circulation are by a Bosch bruschless pump. The system has no pressure and its cool. Then temp are only 26 Celsius on the alternator and the cooling water. This winter i will investigate to make my own regulator. But it shard to get time over with all demands 🙂 The alternator I have are from a Renault 155Amp but I bought a Porsche/Bugatti/Phaeton alternator today and that one are 190 Amp I friend to me have tested this one in his tow boat and it source 276Amp over one hour. But he has a too simple external regulator.

-

Thnx Nick It runs on its own internal cooling system only for the alternator throw a seawater heat exchanger DC 60 from Bowman in Birmingham 🙂 https://ej-bowman.com/wp-content/uploads/2020/09/DC-Oil-Cooler-Issue-K-English.pdf The water to the heat exchanger are coming throw a seawater filter. The source are the inlet for cooling the engine. Alternator have an efficiency of only 50%. (I have measured this value in a test bench) By 150Amp it’s a heating element of about 2000 Watt distributed by a build in fan. The heat are the biggest problem to get out more amp from the alternator. Build in regulator reduce the amp by the heat. By mistake a run out of cooling, then the alternator reduce down to 15Amp, the surface temp was 50 degree C. If you only travel in channels with sweat water and you can get water throw a filter then you probably do not need a heat exchanger. If you do not have a seawater cooling for your engine cause weed etc. then you can use a heat radiator from a car with a fan instead. Everything started up by a friend rebuild his Volvo Penta by purchasing a used alternator from a scrap Renault for only 40£ 5 years ago.

-

DanKim started following Water cooled Alternator

-

Hi everybody I find on this forum that you have find the Renault / Range Rover alternator as possible to up grade your alternator. I am not a talker, I have done it in my sailing yacht and also my brothers sailing yacht since three years ago. Running for the four season now. I have 10 year old ship with at Yanmar 54 hp and my brothers ship are 5 years old and equipped with at Yanmar 104 hp. The alternator have its own cooling system with at Bosch brush less water pump and a heat exchanger see water cooled in line with the impeller for the cooling to the motor. I have 540Ah LiFePo and my brother 1400Ah LiFePo. The temperature of the alternator are 1 degree Celsius warmer then the seawater. My brother have two alternators. The original Hitachi of 125Amp runs burning hot. Its not a nice smell from this one. They are not made for charging LiFe. I will replace that one this winter to the water cooled. My alternator charge in the beginning about 200Amp and after some minutes go down to 130Amp. I have change the ratio to the alternator by +77%. When idling at 650rpm it charge 95Amp and at 800 rpm it charge 130Amp. All regulators are made for lead acid (Ballmar have one for LiFe but I am not impressed of that one!). A friend have mounted the water cooled 190Amp alternator for VW Toureg and it works also great. He have a separately regulator and he use to charge 200Amp. He also have LiFe I hope I have filled in a lot of doubts and questions about those alternators. Sailing regards from Stockholm