-

Posts

131 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by spicemouse

-

The realities of being a live aboard mean that I am in the crap (only one cassette left, and now very low water). I'm a fair distant from a station and shops. I really do need to get moving soon. If I can get this fixed and it works for a few months, okay. At least I know how to fix it next time, and how to get the parts. I'll be a few weeks ahead of myself this time. It's clearly an old part, whether it came off this boat or was bought as a replacement I'll never know. I'll speak to R&D about a new damper, but I'd still need a spacer too. That's weeks away. If this part let's me cruise onwards I'll be happy.

-

Could be, potential both parts aren't parallel so slowly wears over time.

-

Not 100% sure that this is, but both metal sections have three jaws. It's very very similar to the old part. Your can see that it looks like it's been welded in the past.

-

It felt like some canal god is playing with me and planting the parts I need!

-

That's the words I was looking for!

-

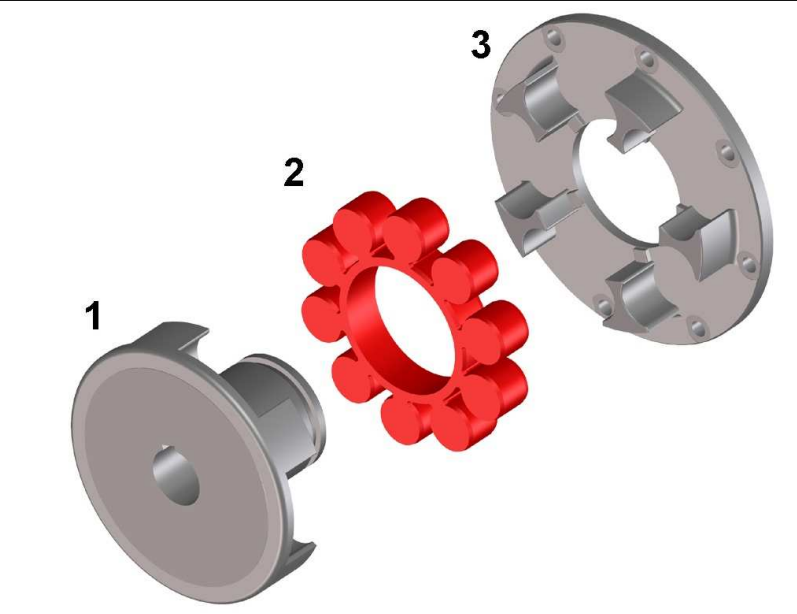

PLOT TWIST: This is an extremely unexpected update. I'd previously sent away the old parts and was speaking to people about spacers. Today I was tidying up my backroom and storage space, and came across something most unexpected: It looks like a previous owner maybe knew the old coupling was going, as they bought an almost identical TSCHAN damper coupling like the one I took off! It's a five lug one, rather than my old 6 lug but the spline is the same. It also comes with a flywheel plate so the number of lugs shouldn't be an issue. You cannot imagine how surprised I was finding this! I must have looked at it after I bought the boat but I'd have no idea what I would have been looking at. Anyway, I tried to remove the old flywheel plate but it couldn't fit out the housing. Tried to prop up the engine and remove the casing, but it's stuck and I can't see how to get going. I'll try get someone more experience over this coming week to get it off and then fit the new/old/surprise coupling.

-

Weekend update: I'm going to try and go for a R&D damper plate. It's about 25mm, so I need 20mm of spacing. Thinking I'll use these tube spacers, sound okay?

-

I'll give them a ring when I can, been busy in work sadly. Has anyone tried spline adaptors? https://splineshop.com/product-category/spline-adapters/

-

I've contacted a few fabricators about creating a new part (I might go with a steel part instead of aluminium). This seems like the easiest, and then I'd order something like this https://e-rubber.eu/product/s-145-coupling/ to replace the rubber. Sadly T. Norris were unable to help. I'm still looking for local aluminium welders, but fear that the amount of new bit we'd need will put most off. I'd again need the rubber part. I'm waiting to hear back from R&D about their damper drive plates. This might still be the cheapest easiest option if they actually make a 13T version (which I can't see on their datasheets http://www.randdmarine.com/downloads/RandD_Damper.pdf) Thanks! I'm glad it's interesting too. These forums are such a great resource for folk like myself, and hopefully this post might prove useful for the next boater who looses an old coupling!

-

I think it's the year of manufacture, 03/1963 I can get accurate measurements of it though, so finding a new rubber part should still be possible. They seem to come in all sizes.

-

I've not looked as I thought I'd most likely end up having to replace all of it. Maybe I should ask about welding first.

-

I found the parts, but they are all very worn and deformed: I'm no expert on welding, but I don't think they could be reused without a fair bit of work on them. Hadn't considered this option though.

-

I might be well off here, but are R&D plates quite flat? I saw them discussed earlier and I think the gap in my system would require some sort of spacer on the flywheel.

-

Got a ball park quote for ~£4k for that, which would be nearly terminal! (they always wanted to replace most/all of the system). I'm hoping it'll be faster, 8 weeks I think I'd have to get a tow closer to a service as I'm about 5miles from the nearest Elsan point 😬

-

It's a about 200g, maybe 1/4 the weight of the other part. I'm thinking aluminium. No scales aboard sadly.

-

If I had one I would.. My hand & magnet tells me it's light stainless steel or aluminium

-

Sunday update: I've just had a look through all the advice since I was last online yesterday evening, that's a lot of links and things to follow up! I am a bit worried about finding a new part in a price range which is reasonable. I'll have a deeper dive later and maybe make some calls on Monday. For the coupling, I finally removed the last section this morning: I think someone wanted a closer look at the splines on the pump, bit rusty but straight to my eyes: So the next step will be finding a part. Is it possible to get some sort of adapter sheath that slips over the slides and provides a smooth surface for the modern versions to connect with? Does that make sense? I realise I don't have the vocabulary of technical terms for this.

-

It's quite worn on the faces of the jaws/blades, clearly been running metal on metal for some time. I think this is the part I'm looking for: http://www.industrialbearings.com.au/uploads/catalogs/baws014-ex-gbr-2_1343603272.pdf The TSCHAN-S SV (by Ringfeder). From the chart in the PDF I'm hoping the replacement will be off the shelf, though it looks like it uses a pin rather than splines.

-

Ended up using a spanner and gently levering it off with a pole, mm at a time turning regularly. Maybe the diesel did it's thing too, though hard to say how much made it to the splines. It says, 3 1963. That can't be the date surely? Anyway, the other side will be off soon as I get the allen keys. Then it'll be a matter of finding a replacement and working out how to fit it.

-

All I have to hand is WD40, diesel, and petrol (which I don't fancy using)

-

I've managed to recovered I think all of the old coupling that hasn't been vaporized. And I'm using a screw driver and hammer to push the coupling off. Now the screwdriver isn't wide enough I'll need to think up something else. Spline grooves says visible now through the gap.

-

Sorry Tony, I'm often trying to get as much in advance I can but not knowing what's the important part and having limited space & hands can be tricky. This is my current situation. I'll have allen keys later for the plate on the flywheel. I'll try the other ideas for the one on the unit, though I don't know where the squirting should be aimed.

-

The engine isn't loud at all, but it's also far away from the driving position, I'm never near it in drive, only neutral. Also, it's probably been like this for years, long before I came along. Any tips on removing something that's attached in the middle like this? Do I need a special tool?

-

I'm not surprised after 25 years! I can give this a go tomorrow when i've got someone to watch the prop or do the turny bit. Or turn the prop and watch the other bit. Either way I can't do it alone.

-

So it's a TSCHAN coupling (can read the brand off the plate). I can't remove this today as I don't have a decent enough allen key: And on the unit: I think it used to look something like this: but now it's missing the rubber and the teeth on the engine side of the coupling. It's likely this coupling hasn't been touched in ~25 years, so maybe just old age? Next job is to remove the broken couplings, clean up all the waste it's created, and find myself replacements. Also, the hydraulic unit turns fine in neutral (which I think is good!).