-

Posts

332 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by Steve56

-

-

6 minutes ago, Alan de Enfield said:

Thankyou - I saw that in the Industrial Engines manual I have, but how does that equate to the manual that says for the Indirect injection engines you should use API CF ?, particularly when it says that CC is for moderate to heavy duty engine use (not typical narrowboats)

Can't really explain that. There does seem to be a lot of contradictions over the years and also over different publications of the manuals. I am just giving an opinion of how things were when I was employed first as an R&D engineer and then service engineer with the company. That was back in the day when Lister Petter owned the company and when most of the engines we are talking about were manufactured. Since then the company has had many owners, with most parts being made abroad so really not in a position to talk about these latterly built engines.

-

14 minutes ago, Alan de Enfield said:

The manual covers all Alpha Engines both in Industruial and marine usage (and also cover marine gearboxes).

IT does say that for any 'long running installations' (typically Generators, Fishing boats, industrial equipment etc ) that Lister Petter should be contacted for recommendations on oil types. I'm just trying to understand why we should not follow the manufacturers guidelines. I'm just hoping that as a LP emplyee Stebe56 may have some answers.

It goes on to describe the different grades and their pros and cons :

API Service Category CC:

Service typical of certain naturally aspirated diesel engines operated in moderate to severe-duty service, and certain heavy-duty gasoline engines. Oils designed for this service provide protection from high-temperature deposits and bearing corrosion in diesel engines, and also from rust, corrosion, and low-temperature deposits in gasoline engines. These oils were introduced in 1961

API Service Category CF:

Usage : Indirect injection

Service typical of indirect-injected diesel engines and other diesel engines that use a broad range of fuel types, including those using fuel with high sulphur content; for example, over 0.5% weight. Effective control of piston deposits, wear and copper-containing bearing corrosion is essential for these engines, which may be naturally aspirated, turbocharged or supercharged. Oils designated for this service have been in existence since 1994 and may be used when API Service Category CD is recommended

(from the manual : LPWS2, 3 and 4 - two, three and four cylinder, indirect injection, naturally aspirated water cooled diesel engines)

API Service Category CG-4 - 1994:

Severe duty API Service Category CG-4 describes oils for use in high-speed four-stroke-cycle diesel engines used in both heavy-duty on-highway (0.05% weight sulphur fuel) and off-highway (less than 0.5% weight sulphur fuel) applications. CG-4 oils provide effective control over high temperature piston deposits, wear, corrosion, foaming, oxidation stability, and soot accumulation. These oils are especially effective in engines designed to meet 1994 exhaust emission standards and may also be used in engines requiring API Service Categories CD, CE, and CF-4. Oils designed for this service have been in existence since 1994

This is the relevant part relating to engines running at low duty cycles ie engines in narrowboats.

-

10 minutes ago, Tony Brooks said:

I am interested in the discrepancy in API rating between the manual and what Steve86 recommends, but that manual may be a generic one for industrial engines while experience showed up problems in canal use.

As you say Tony there are various manuals dependant on if you are using the engine for industrial use, normally high loads or marine use. Even with marine use the engine could be in a sea going vessel and again running at high load. The problem always was that in a narrowboat the engines never ran much above idle speed which is what caused the problems. Another problem is that people put a modern diesel engine into a narrow boat and then try to get them to run as slow as possible. Maybe to try and get back to the days of the old slow speed diesels. But a modern engine was never designed for this sort of work. So always a compromise. From experience as a Lister engineer the best way forward was to use a relatively low spec oil to ensure bore glazing wasn't a problem.

-

2 hours ago, Ray T said:

Slightly off topic, but as engine vibration has been mentioned, we had side rail bearers fitted. There were two resonance points as certain revs where the engine vibrated badly, I can't remember what they were now.

The side rail bearers cured this. Also, we had the engine bearers changed at the same time.

The 3 cylinder engine suffered badly with vibration issues. The mod you show in your photos was something I came up with when working as an R & D engineer at Lister Petter. It did make an improvement to the way the engine ran.

-

1

1

-

-

2 minutes ago, Tgno3 said:

Am calling out canal rescue today!

this is exactly what my engineer a couple of wks said it was and I have bought 15w-40 on his recommendation, need to change so will change filter then too, and under the advice of all the above change every 100hrs.

I have tried clearing it it’s ALOT of smoke

and not entirely sure it worked

She starts well even in freezing weather

Make sure the oil is API CC. Should say on the can. If not sure just post what it says and I'm sure someone will advise.

-

6 minutes ago, Tgno3 said:

When I bought the broker said had services from the owner, but obviously this doesn’t mean it was done properly.

has no history, unless I’ve been told fibs to.interesting Ray T, maybe the reasoning for the bolt coming unthreaded, maybe something to consider.

here are pics of the exhaust spitting if interested, also bit of context, this was after having been run for 25 mins)

(disclaimer- stopped engine after seeing how much was coming out, I am not polluting the canal anymore)

The other issue with these engines was bore glazing. It was a common fault if running under light load and using a high spec oil. Ideally you should be using an API CC oil. If that is the case you may be able to clear it by ensuring the correct spec oil then run in gear at full speed. Keep an eye on temperatures as your cooling system may not be man enough to cope. And yes I do know that CRT say you shouldn't do this.

-

5 minutes ago, Ray T said:

We have an LPWS3 in our boat, using standard components.

I was not happy with the OEM header (BLMC) tank as it was difficult to fill due to a beam over the filler cap.I replaced it with a Renault header tank. Easer to fill and holds more coolant. (Our late dog Millie inspecting the job) The tank is above the engine height.

The alloy tank, from a classic car site, is for the central heating. It replaced another rather ugly BLMC tank.Those tanks were always a weak point. Would tend to part from the engine after a bit of vibration. Best thing to do, as you have done is to replace with a remote tank.

-

12 hours ago, Tony Brooks said:

I think these engines may use hydraulic valve lifters and if the engine oil changes have not been done diligently they could be causing poor combustion during acceleration and exhaust smoke.

You are quite right in saying that this range of engines uses hydraulic valve lifters. I've worked on a number of these in the past that have been damaged by lack of maintenance. If the oil is not changed regularly it will cause the lifters to jack open and the valves to hit the piston.

In my opinion one of the big problems with this range of the engine was that with the old Listers you could get away with a lot of abuse and lack of maintenance and they would just keep going. A lot of people thought they could do the same with this model but found out they couldn't.

The Alpha range of engines are good reliable engines but must be maintained correctly.

-

Sounds like a faulty connection somewhere. If you have voltage in the battery, which you must have done to start engine then as soon as you turn ignition on the voltmeter should give a reading. This would happen regardless of whether the alternator was charging or not.

-

14 minutes ago, Lee Crook said:

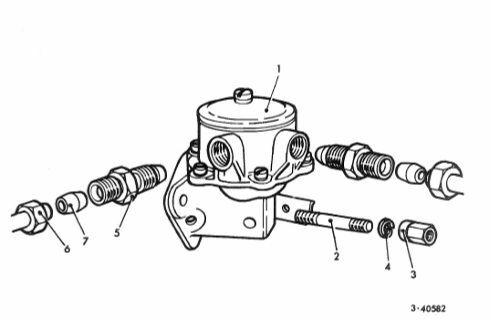

The one I removed was on the connection from the oil pump to the lubricating oil pipe (part no. 8 on the drawing) and you can see the shape it was compressed into when forming the seal. The one that looks new/unused was in the oil sump and I found it when scraping/scooping out the last of the oil dregs.

They are the small bore oil pipes which feed the rocker bushes.

-

There should only be one of these used in the pipe fitting. It is basically doing the same job as an olive. The pipe is pushed through the threaded fitting, the rubber seal is slid onto the pipe then everything is assembled into the fitting.

-

1 hour ago, Tasemu said:

The end cap of the alternator appears to push up and into the insulation on the side of the acoustic box. I'll try to have a proper look to see if i am able to access the screws to remove the cap. Looks really tight though.

Yes if I remember correctly they are done this way so they can get cool air. It will either end up at a louvred panel at the back of the housing or possibly go into a plenum chamber. Either way you will need to take housing appart to get good access.

-

11 hours ago, Tasemu said:

The AVR is no 14 on the diagram. You will need to remove the plastic end cover to access it. Normally they have a small potentiometer on them to allow for voltage adjustment. Firstly though you will need to ensure engine speed is correct and alternator is giving around 52 Hz off load.

-

One other comment after taking a closer look at the photos. From what I can make out your pre filter is mounted to one side of the engine, but not fitted to it. You then have a short length of solid copper pipe which runs from the filter to the lift pump. If that is the case this length of pipe should be a flex pipe and not solid. This is to allow for engine vibration. Again if this is the case it could certainly cause the leaks in the pipework.

-

Here's a diagram of what would of of originally been fitted. As you can see the fitting had a male cone on it, which would form a seal in the pump. All pipework would originally have been 5/16" which is still readily available. If you need any of these fittings or any other parts then it may be worth talking to Marine Engine Services (Midlands) who I'm sure can give good advice.

-

-

Yes the SL engines were all imperial and used mostly AF. There are a few exceptions such as some of the fuel and oil unions which would be BSF/Whit sizes

-

-

Interesting that he has a mix and match of imperial and metric fittings, or it certainly looks that way. I know people try to do this but it is bad practice and never really successful.

-

Many years ago I installed a Taylors heater on an old boat of mine. I supplied the fuel from the main fuel tank that was at a lower level than the heater. All I used was an electric in line pump. Not the SU type but the modern electronic type. The sort of thing which is available quite cheaply from somewhere like ASAP Supplies. It worked well and never gave a problem. This type of pump runs continuously and give a constant pressure. Not sure of the power consumption but probably very low.

-

-

The engine does have an earth strap ( battery negative). It runs from battery negative, through the earthing solenoid and then connects to the engine. The solenoid closes to make the connection when either starter or heater plugs are operated. During normal running it will be open to take the negative off the engine.

-

-

1 hour ago, steve.sharratt said:

That is interesting and I think that’s what the engineer who did recent work on the box was talking about. Do you have a recommended supplier and a rough cost?

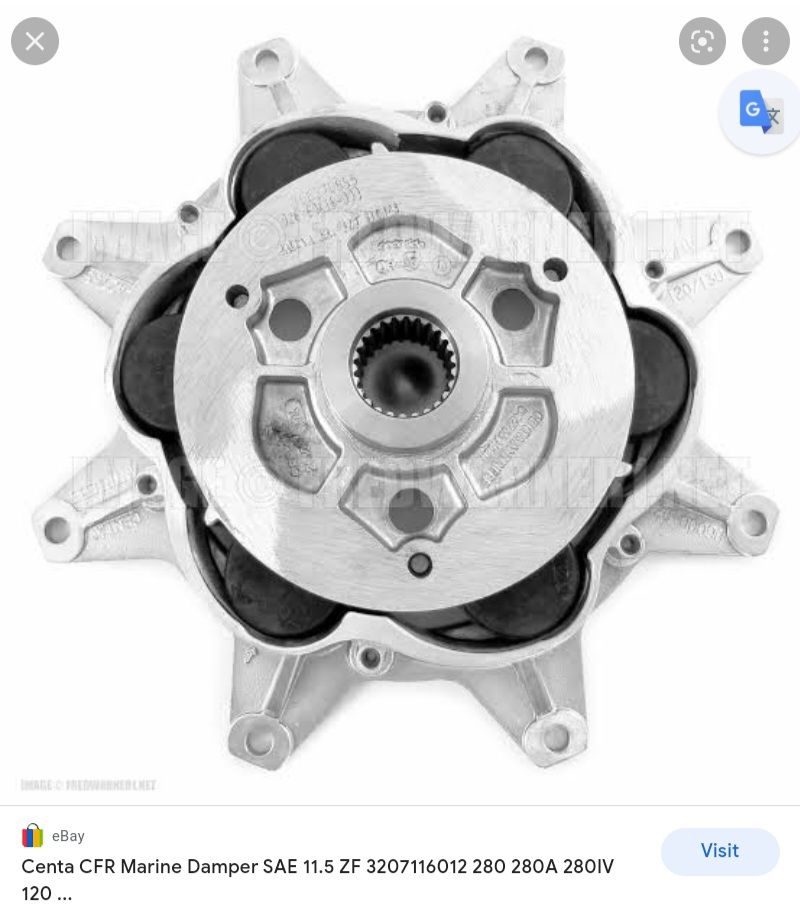

The Gardner I did this mod on was the same set up. Trad style engine room long prop shaft and a big propeller. That's a lot of inertia. I've bought a couple over the years directly from Centa Transmissions Ltd. They were based in Shipley, close to Bradford. But I think now they have moved. I used to get them through a work colleague who was there marine sales engineer, but unfortunately he has now moved on to another company. I'm not really sure of the cost, but considerably more expensive than your typical R & D plate. But in my opinion so much better and well worth it.

Lister petter Lpws3 exhaust spitting/ leak

in Boat Building & Maintenance

Posted

The 3 cylinder engine was the worst one for vibration issues. The modified engine bearers were only ever available for that model. The 2&4 cylinder models just stuck with the standard feet.