-

Posts

332 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Steve56

-

The early marine engines used a Lucas starter motor. Originally there was a choice of isulated or earth return. Lucas then stopped supplying the insulated starter hence the use of the twin 4ST solenoids when insulated earth was required. Moving on to later engines Lucas stopped supplying starters altogether so Lister moved over to using Nippon Denso starter motors. These later starters can be fitted to earlier engines with no other modification to the engine.

-

What you have there looks to be a VDO oil pressure sender. That pipe will be the feed pipe. Can't see exactly what engine you have, but if it is a SR engine the pipe will run to the forward end of the fuel pump housing. If an ST engine then it will run around to just above the oil filter on the crankcase door. Both of these engines would have originally used a mechanical gauge if ordered as an extra from Lister.

-

I can quite safely say that. During my time as a Lister Petter engineer I visited the Sabb factory in Bergen to assist them with the engine. Also as a lifeboat it is necessary to be able to run the engines out of the water for short periods, hence they would be 100% keel cooled. As the photo shows the engine is fitted with a dry exhaust.

-

This engine would have been keel cooled so no worries about corrosion. Not really much of a connection. Sabb would purchase a marinised engine from Lister Petter and then carry out various modifications to make it suitable for lifeboat use.

-

I would second that. They have built a number of barges as well as many other styles of boat over the years. The quality of there steelwork is excellent. Dependent on size should be able to go across the K&A to London. It would certainly be worth having a chat with them.

-

Pointless sealing it as it will only mask the problem. There should not be coolant at this point. Possibly an internal leak in the tank, head gasket failure. Maybe external water running back down the exhaust. As a start maybe remove the exhaust and see which way the water is coming.

-

Seems odd. The marine version of the LPWS4 was not introduced until the early 90's when the only marine build was a 42. The build 45 only followed on a couple of years after that.

-

The flywheel housing will be the same regardless of what the engine is being used for.

-

Looks like either an SR or LR engine. It's variable speed and is running in an anti clockwise rotation..

-

-

There were marine versions of the Dellta engine. Not sure that they were marinised by the Lister factory. Possibly marinised by Rodger at Cotswols Diesels on behalf of Lister.

-

Certainly looks that way as the engine shown in the photo and the engine number shown are totally different engines.

-

As Richard has said it is definitely not a Lister LPWS4. It's a Mitsubishi engine. Lister did make these under licence for Mitsubishi and actually badged some of them as Lister. It was the Mitsubishi S4S engine which Lister called DWS4.

-

This range of engines was built between 1931 and 1952. If it is fitted with the correct number plate that would make your engine1942.

-

The number you have shown is a Lister part number. So my guess is that it will be the part number of the item it was stamped on, possibly crankcase.

-

That'll teach me to check the date first.

-

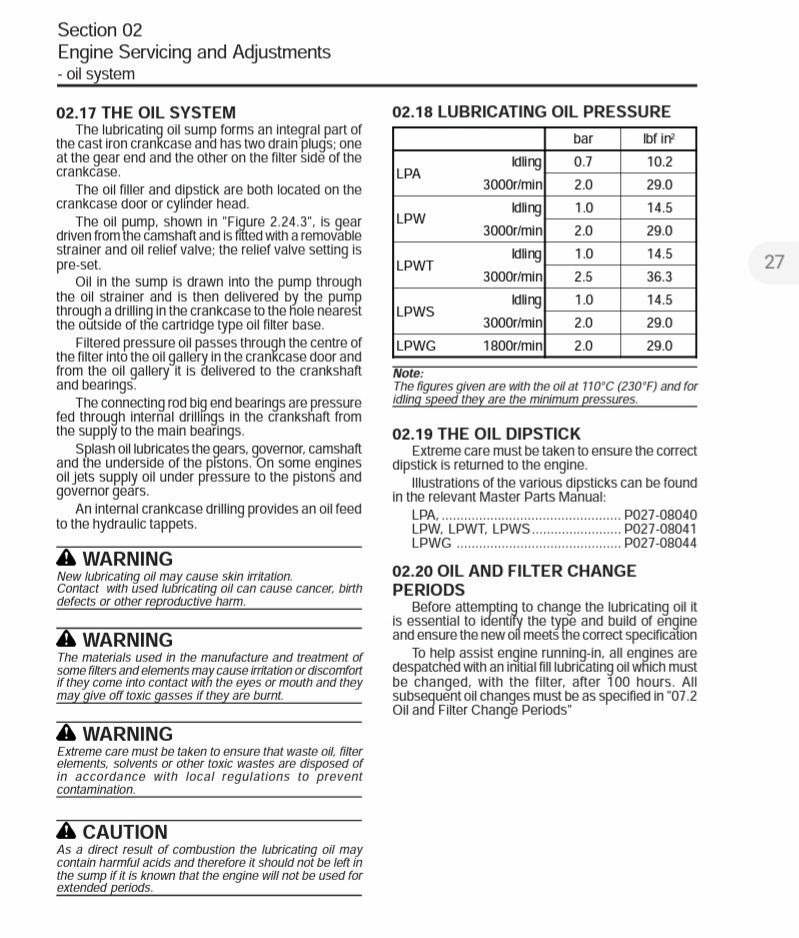

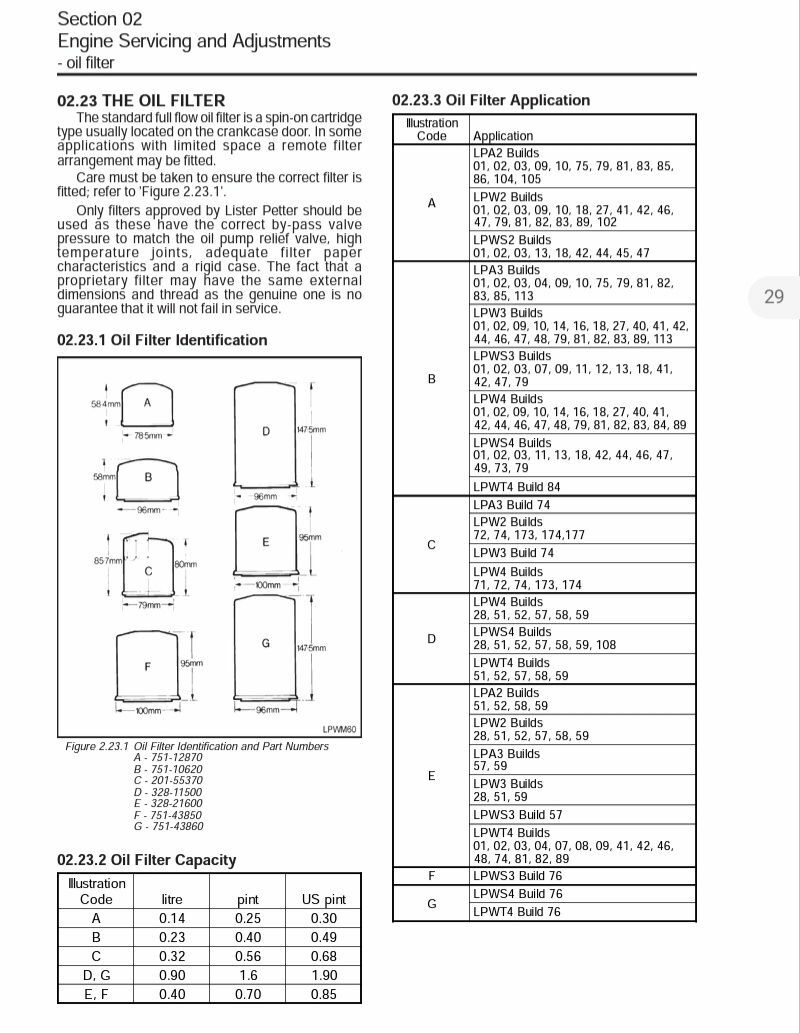

Here's a little info that may help. As you can see the Alpa engines always had a relatively low oil pressure from new and this causes no problems. Is your idle speed correct, it should be around 950 rpm under load. If it has dropped off which is quite common with this engine your oil pressure will also drop off at idle. Also info on the various filters fitted to the Alpha range of engines. Yours should be fitted with with letter B. You can check against the dimensions to see if you have the correct one. But in all honesty it will have no bearing on your oil pressure whichever one is fitted.

-

Back in the day this is the type of header tank supplied by Lister as an optional extra for use with the Polar manifold. It would be piped up to the manifold overflow pipe. The manifold would then be fitted with a plain non pressurised cap, and the pressure cap would be fitted to this header tank. Also the original water pump fitted to that engine would have been a non bypass type, therefore it would have a standard type thermostat without the extra flap fitted. Also noticed previously mention of thermostat jiggle pin. On the set up above the jiggle pin was removed on assembly. This was to alow a small amount of water circulation before the thermostat opened. As the pump was non bypass this ensured there were no internal localised hot spots. By the time Lister moved over to the later type cooling system the engine was also being fitted with the later pump. If the pump has ever been changed the chances are it will be the later type pump as the early pumps were made obsolete but were totally interchangeable.

-

Yes they do spring back when you release them. But this will not cause any problems as there is no oil in them. They will only operate again one the oil has circulated through them. I like to do it this way just for the sake of clearing out any dirty/contaminated oil.

-

When injection pumps are removed from these engines the shims stay with the block, not the pump. The reason for this is that the pumps are pre shimmed on manufacture, so every pump will be the same. Any differences will be with the tolerances on the crankcase and fuel pump tappets. As you say it is possible to always leave on pump in to keep the setting. If done this way it is important to wind the stop lever back so it is the pump, not the stop lever holding the rack in position. The problem with support is that when the engine was originally built it was built by Lister Petter themselves who would give all the support needed. When Lister Petter shut down many years ago the name was sold on and there have been a number of owners over the years. I suppose another thing is that when the original engine was built it was all built in house at Dursley. This would include all the casting in there own foundry, all machining in there own machine shop. So Lister had total control of the quality. After the shut down of the factory and when made elsewhere it was more just an assembly operation with parts being supplied by outside contactors, and not all of them UK based. Going back there were a number of the ex Lister engineers, including myself that started working for themselves. Unfortunately as far as I am aware most of us have now retired.

-

As you say the Alpha range does need proper maintenance, unlike the older Listers that would take a lot more abuse. They definitely need the regular oil changes. If the oil is allowed to get to black and thick it will cause the tappets to jack themselves open, at best holding the valves off there seats, at worst causing the valve to hit the piston. As has been mentioned when the head has been removed it is important that the tappets are compressed before spinning the engine over. Lister did supply a special tool for this job. Personally I would always remove them and squeeze in a vice to ensure all the old oil was out of them.

-

Looks like one or more of the pumps are gummed up or tight. That's about the oly thing that would make the rack that stiff.

-

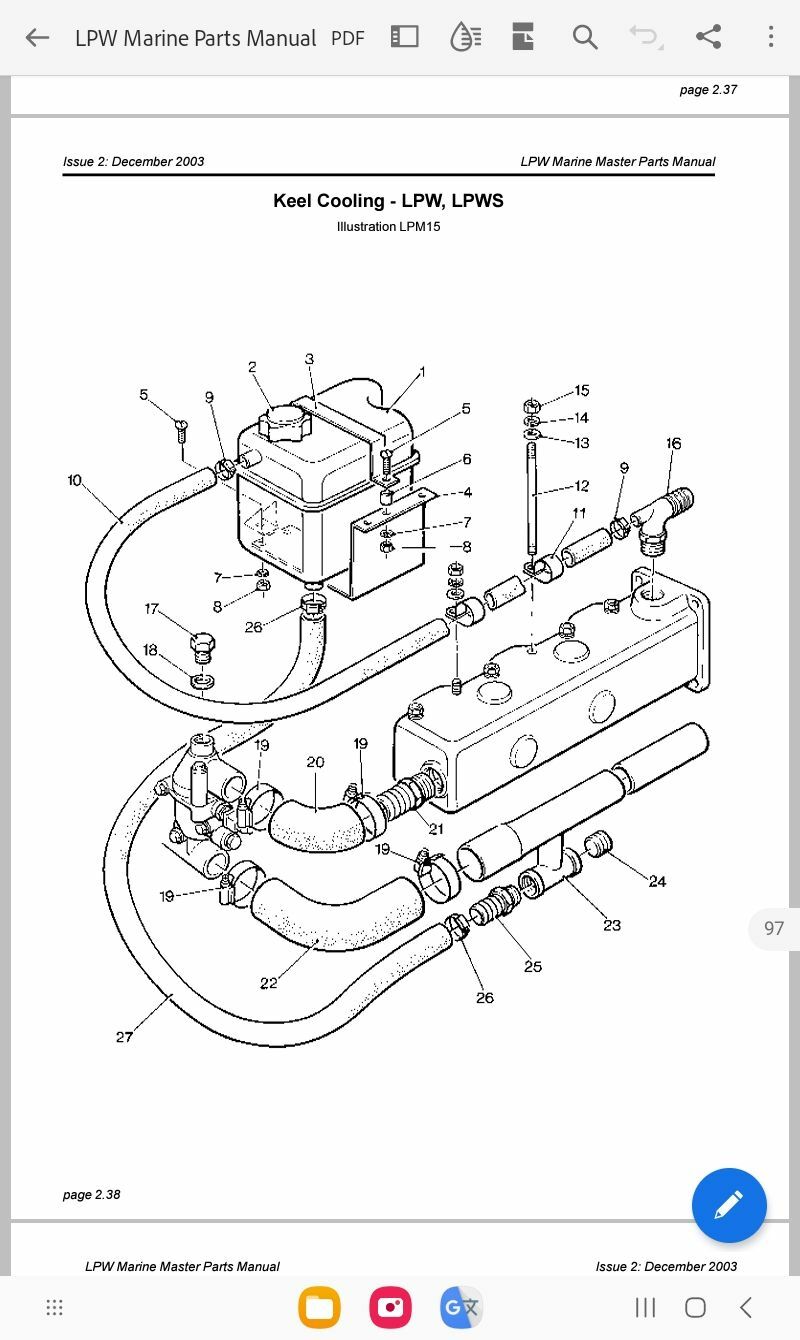

One thing that could give an indication of pump operation. If you have the standard set up as per diagram remove the filler cap and run the engine up to a relatively fast speed. You should then see a steady trickle of water being returned to the tank via hose number 10.

-

As you say not the correct Lister part, but would make no difference to the operation.

-

As you rightly say the thermostat is basically a normal wax state, but with the extra flap on the bottom to seal the bypass as the stat opens. What is shown in the photo is the hot water feed to the calorifier. If no calorifier was fitted then the temperature switch would fit directly into the pump. When a calorifier was fitted or a kit ordered then Lister would supply this special union to allow for fitting of the switch and the hose. The return hose would connect onto a t-piece which was on the return pipe which can just be seen at the bottom of the photo.