RedsfanUk

Member-

Posts

22 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by RedsfanUk

-

Victron 712 battery monitor question.

RedsfanUk replied to RedsfanUk's topic in Boat Building & Maintenance

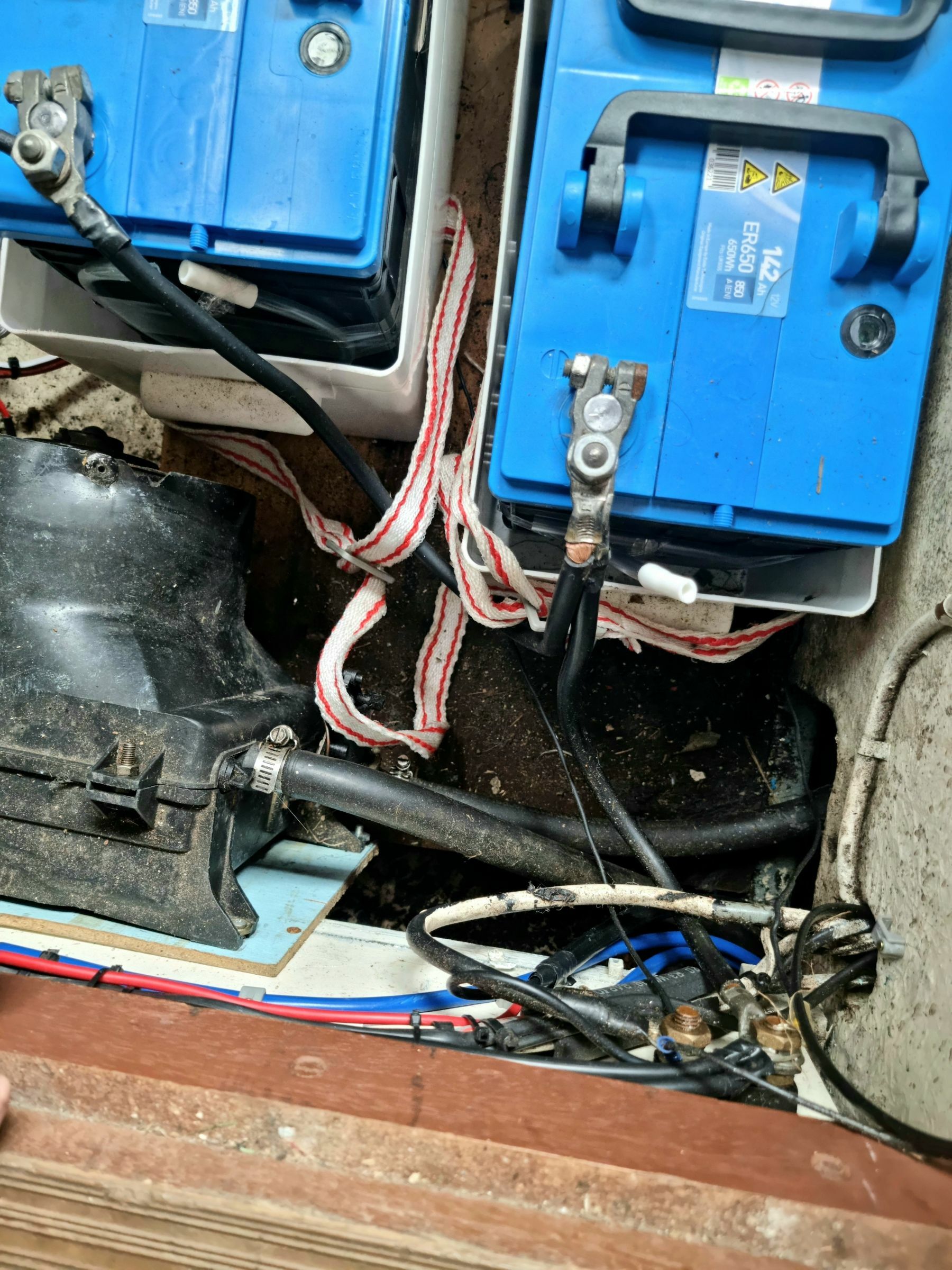

Thanks for all your replies,really appreciated. Sorry just to summarise(for my ultra cautious novice self) so as I see it...the negative cable I've marked in the photo to my load side of shunt,and the cable I've attached ready, to go to my negative batteries(in parallel). -

Victron 712 battery monitor question.

RedsfanUk replied to RedsfanUk's topic in Boat Building & Maintenance

Sorry no not at all,I'll be back at boat shortly and will annotate the photo 😊 -

Victron 712 battery monitor question.

RedsfanUk replied to RedsfanUk's topic in Boat Building & Maintenance

Thanks for all your replies,much appreciated! -

Victron 712 battery monitor question.

RedsfanUk replied to RedsfanUk's topic in Boat Building & Maintenance

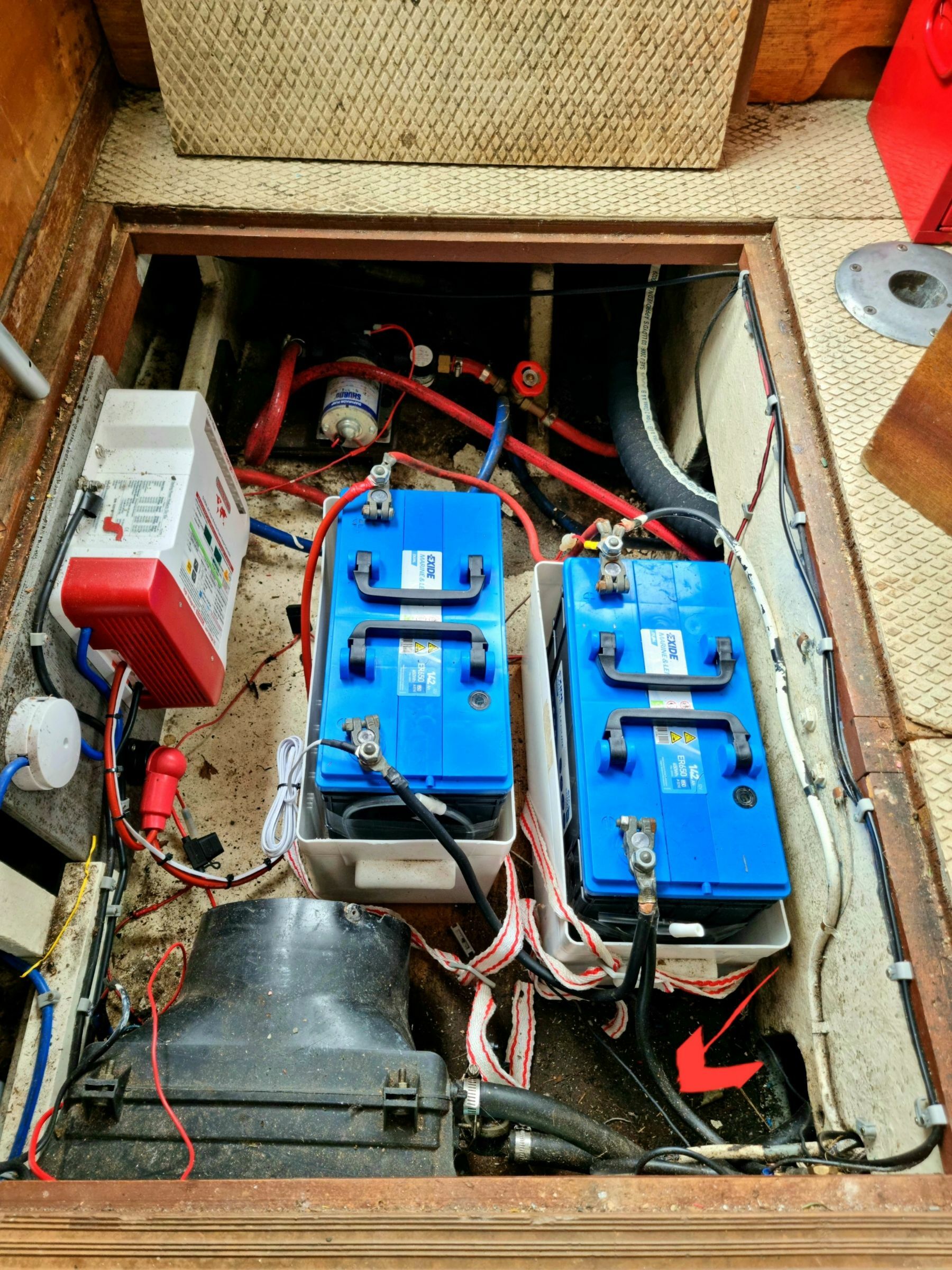

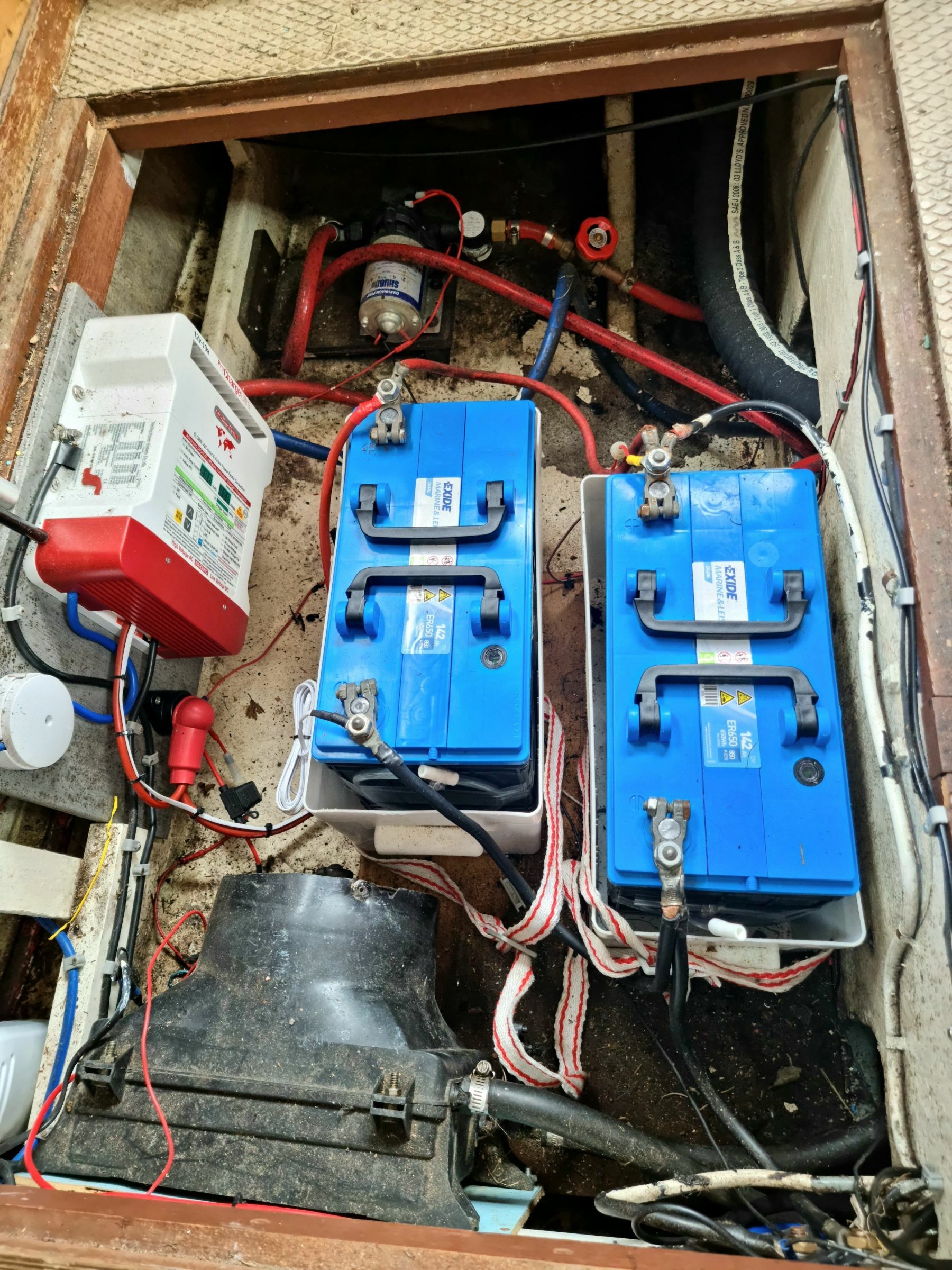

I don't know if these photo's help. This is how it was all wired up originally....there's a diesel blown air heating system,and 100w solar wired in there. -

Victron 712 battery monitor question.

RedsfanUk replied to RedsfanUk's topic in Boat Building & Maintenance

But that cable on the photo is my negative feed from the batteries(they're in parallel) from the battery master switch. Sorry I'm puzzled 😀 -

Hi,just a quick one please. Complete novice at boat electrics,I'm installing the victron shunt to my system. The load side I just want to be sure about. I'm guessing the shunt goes between my batteries and the battery isolator switch?(see photo) Thanks for your time

-

Thanks all for the replies and the advice,it would be my first Nb and big purchase,need to get it right. So all the advice given is a big help,appreciate it

-

Ok thanks put my mind at ease abit. Honestly didn't realise ? would delete it if I could.

-

Ahhh

-

Hi, it's a 2011 boat

-

Hi, I've just had a survey on my potential first boat purchase ,just looking for opinions/advice on the hull aspect (pitting) does this look a good hull condition to you guys? A Hull sides: Based on the thickness readings taken, it is indicative that the hull sides were originally fabricated from nominal 6mm steel plate. Ultrasonic measurements were taken with a Tritex 5500 triple echo meter with a 13mm probe. The side plates had a covering of marine growth and were not pressure washed prior to inspection. Sample areas were selected at random along the side plates, and the marine growth and paint coating was removed with a hand scraper in these areas only. From the sample areas selected, ultrasonic measurements show the plate thickness to be between 5.8mm and 6mm, which are within acceptable limits. Moderate pitting corrosion is present and the maximum pit depth measured was approx. 1.8mm. The steel thickness may be thinner, and deeper pitting may be present in the areas where the marine growth and paint coating was not removed for inspection. The steel thickness may also be thinner than the readings obtained if any internal corrosion is present, as the meter cannot discriminate between echoes from the back wall of the item being measured and any corrosion on the internal plate. Moderate wastage corrosion was noted around the waterline and through hull outlets, and the hull requires blacking. Rec 4: De-rust and the areas around the waterline and through hull outlets, and then re-black the hull. NB It is important to keep the hull protected by regular re-blacking at maximum intervals of approx. two years, and maintaining adequate cathodic protection to help minimise any future pitting and corrosion to the hull. B Hull bottom (base plate): The hull is flat bottomed with an overlap to protect the chine weld. Based on the thickness readings taken, it is indicative that the hull bottom was originally fabricated from nominal 10mm steel plate. The bottom plates had a covering of marine growth and were not pressure washed prior to inspection. Sample areas were selected at random along the bottom plates, and the marine growth was removed with a hand scraper in these areas only. From the sample areas selected, ultrasonic measurements show the plate thickness to be between 9.6mm and 10mm, which are within acceptable limits. Widespread pitting corrosion is present and the maximum pit depth measured was approx. 1.8mm. The steel thickness may be thinner and deeper pitting may be present in the areas where the marine growth was not removed for inspection. The steel thickness may also be thinner than the readings obtained if any internal corrosion is present, as the meter cannot discriminate between echoes from the back wall of the item being measured and any corrosion on the internal plate. The bottom plates appear to have no visible coating, which is normal industry practice, but is not best practice. Weld protection is provided by a sacrificial overlap of the base plate which has approximately between 10-15mm of wear edge remaining. Rec 5: It is generally believed that the base plate of the hull does not require blacking as the coating would quickly be worn off under normal use, and is normally not possible due to restrictions placed in the dry dock. This however does not always appear to be true and the coating can last just as long as the paint system on the rest of the hull. I recommend that wherever possible the base plate be coated to protect the steelwork and help minimise any future pitting and corrosion to the steelwork. 5 C Counter / Uxter plate: Based on the thickness readings taken, it is indicative that the counter plate was originally fabricated from nominal 6mm steel plate. The counter plates had a covering of marine growth and were not pressure washed prior to inspection. Sample areas were selected at random along the counter plates, and the marine growth and paint coating was removed with a hand scraper in these areas only. From the sample areas selected, ultrasonic measurements show the plate thickness to be between 5.8mm and 6mm, which are within acceptable limits. Light pitting corrosion is present and the maximum pit depth measured was approx. 0.5mm. The steel thickness may be thinner and deeper pitting may be present in the areas where the marine growth was not removed for inspection. The steel thickness may also be thinner than the readings obtained if any internal corrosion is present, as the meter cannot discriminate between echoes from the back wall of the item being measured and any corrosion on the internal plate. D Ultrasonic measurements The diagrams below are an approximate guide to show the general position from where the ultrasonic measurements were taken from, and the plate thickness reading obtained in millimetres. The diagram is not to scale. Starboard side readings: 5.9mm 5.9mm 5.8mm 5.8mm 5.8mm 5.8mm 5.8mm 6mm 6mm 5.9mm 5.9mm 5.9mm 5.9mm 5.9mm 5.8mm 6mm 10mm 9.6mm 9.6mm 9.8mm 9.9mm 10mm 9.8mm 9.9mm Portside reading: 5.9mm 5.9mm 6mm 5.8mm 5.8mm 5.8mm 5.8mm 5.8mm 6mm 5.9mm 5.9mm 5.9mm 5.9mm 6mm 9.8mm 9.8mm 9.8mm 9.8mm 9.8mm 9.6mm 9.6mm 9.8mm 6mm 5.8mm Thanks in advance for any advice given

-

Thanks all for the replies,got a survey being booked,fingers crossed!

-

9months ago it sounds. I just thought under the board where the pump is situated would of been damp too(appears dry)... but the damp appears to be all above it.

-

Ok thanks for the reply pal

-

Hi,so we've been to view to a boat we like,just a quick question about something we've found,that doesn't add up. It looked a nice and tidy boat,but in the bedroom wardrobe, the floor panel is very very damp and so is the back wooden wall of the wardrobe. We removed the wet floor panel of the wardrobe to find the water pump underneath which looked fine and there were cobwebs etc no sign of damp. The seller's explanation was that a new water pump was fitted last year after the last one leaked badly. Which has caused this bad dampness. I am new to this boating business so I'm just thought I'd ask here,does this explanation sound reasonable? I'm going to get it surveyed if I proceed,bit just thought I'd ask for advice. Could it be something really bad?

-

It's something I've wanted to do for some time to be honest, and I'm mortgage free and want to live afloat,worse case scenario and I don't like it,I lose some money on the boat,but at least I have tried it. But I can't see how I wouldn't like it,I have spent countless hours walking by the canal in all kinds of weather,been on boating holidays and loved it. Thanks for the replies guys.

-

Hi and thanks The owner told me it is ready for another blacking to be done(3 years ago was last one) yes I think has a galvanic isolator. It's right next to shorepower feeds.

-

Hi and thanks for the replies. Yes you're quite right it could take longer to complete the sale of house. But all is in place for quicker one,no chains etc. Anyway fingers crossed. I just wanted to get a heads up and start looking now,I do have somewhere to live in the event I don't find a NB for now,and because the boat was so close I guess that tempted me to go view it. The seller of the boat knows my position so we'll see.

-

Hi, In the middle of a house sale that's hopefully being completed very soon (weeks) and I'm looking at buying a NB. I was thinking of visiting the various brokers...but one narrowboat came up for sale right on my doorstep that I've been to view(it would save money rather than having to transport one up) A 60ft trad 2006 Nick Thorpe boat up for 48k,looks very nice. I wonder could someone give me some advice as I'm completely new to this. Now its present mooring is on our local dock lands which doesn't require a CRT license or bss. After speaking with the owner he's just used it as a floating apartment and it's not moved in 4 years since he bought it. Its has around 550hours on the engine(the bay look clean) but hasn't been serviced since 2016. He said it's no survey since he bought it 4 years ago. Now my plan is to be on the canal (marina during the week and weekend cruising) after purchasing a boat. So I would need to have this bss done. The engine not being serviced since 2016 is a major red flag even though it hasn't been moved and has been on shoreline all this time? I would for sure get a survey done,but what other red flags would there likely to be about a boat that's been stood still for so long? Thanks in advance!

-

Hi all, Just an introduction I'm Alan,seriously thinking of looking to buy a NB to live on the Lancaster canal(selling house process at the mo) I posted on a separate thread(missed this one I must be blind ) The idea of finishing work early on Friday and being free to leave the marina and go cruising at weekends(eating out at the pubs etc) along the way is drawing me in. I've done the research,pros and cons....few friends trying to advise me against for various reasons. For example it's a depreciating asset...money pit etc etc. I've taken that all aboard(excuse the pun) but the way of life still appeals to me...anyway I'll be back here with an update at some point,nice to meet you all

-

Thanks for the replies and advice! Yes the marina would have shoreline power,and yes I'd be based on the Lancaster

-

Hi, I am in the process of selling my house,and in need of a change,possibly a narrowboat as an option. From an early age I have been on many boat holidays (Lancaster canal,Norfolk broads etc) and loved them...I have been watching many youtubers,reading up on narrowboat life(Lancaster canal) and its something I think could be right for me. I was wondering if I can get some advice please from you seasoned boaters. Would a budget of 45-55k be good enough for a live aboard? I plan to get a leisure mooring(already enquired) ,and I have a place to stay(address for mail etc) for when I need to get off the boat,so I don't need a residential mooring. I plan to keep the boat at the marina during the week and cruise at weekends only. A typical day during the week I will leave for work (have car)at 7am and not return till 6.30-7pm. Is that feasible for narrowboat life? Any advice at all would be great.