Tractor

-

Posts

120 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by Tractor

-

-

Mooring between St Johns Lock and Halfpenny Bridge, Lechlade.

Watch out for Heffers in this field, they go around in a juvenile 'mob', and will not only lick the boat, and lean on it, but try to eat the rubber window surrounds and the cratch cover

A guy will turn up to collect mooring fees, to explain all this but before this be on the look out for the Heffers.

-

It seems odd that, a mere sum (£650K), can be floating around in some CRT account which has not got a proper justification.

With licence and mooring fees increasing, the prospect of maintaining this lifestyle is fast loosing its justification. I have now doubt many will carry on, and maintain this heritage; sadly this may not be for me.

Apologies for this, depression will lift tomorrow..

-

The bridge close to Dukes Cut is a road crossing which is best to remain closed. For the remainder which are not used for access ‘what is the point’ of installing a mechanism which is costly to install, will require maintenance, and is not necessary.

-

On 30/09/2023 at 12:01, Nb Ceann Caslach said:

The bow thruster worked last time I used it, we haven’t been out for a year. I switched it on this morning and when I switched the isolator on the thruster motor ‘kicked’ for a second or so and the control panel showed the Fault light. I switched it off at he isolator and back on again and the relay on the thruster clicks when the switch is switched on or off. The Fault light shows when it is on. Can anyone suggest where I should look/test with the meter? I suspect a wiring issue somewhere.

Brushes stick in the holders with corrosion?

Give them a wiggle, or rub down, and a good run to clean the commutator.

-

1

1

-

-

The motor, to have a suitable rpm would be 6 or possibly 8 pole. The stator however appears small, there was no mention of power rating, it looked to be no more than 2 or 3kW.

Interesting project, I envy the ability to code the systems.

-

I have two pumps connected in parallel, selected by individual pressure switches. If high pressure is achieved, one pump runs, if high pressure is not achieved two pumps run. This is made by adjusting pressure switches.

-

The water pipe feeding the rads, not the pipe connected to the pump, slip this of slightly until you get a slight spill of water, and push back, secure with hose clip.

If header is up to level, this ensures no air in the heat exchanger.

-

Firefly had a large white gas tank fitted across the bow, forward of the fwd access doors. Leakage could be spilled overboard in the usual way for LPG.

-

-

These are ‘triac’, Voltage control devices, switching the single-phase supply in order to regulate the Voltage, an action which will generate some disturbance seen by the inverter. If the aim is to use spare capacity form the solar installation and ‘dump’ this into the water tank, then the idea is good. Some control will be required to ensure the energy is surplus for use and will not removing energy from the batteries.

As there are many of these circuits on the market, you are right to be wary as the switching may not be tolerated by the inverter, and other devices operating on this supply. Testing in situ is the only way to be sure.

-

-

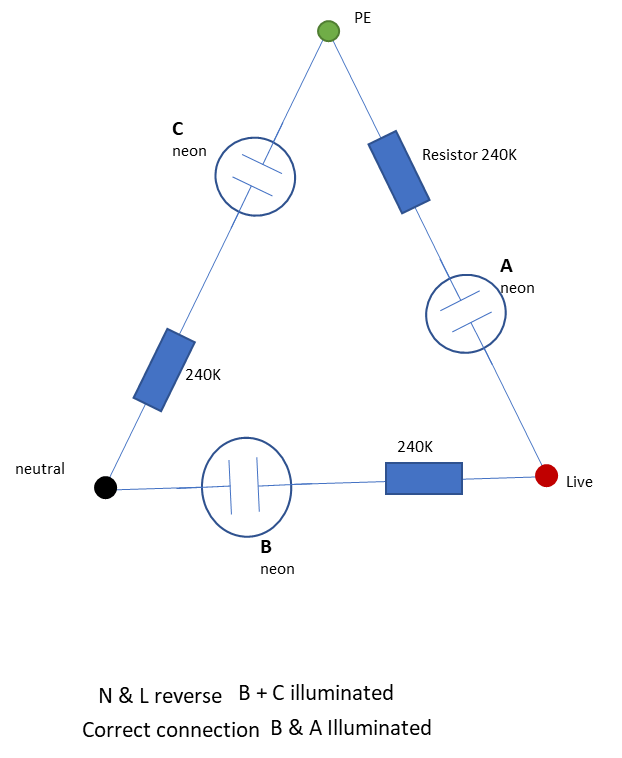

1 phase mains tester ??

-

1

1

-

-

I agree with ‘aread2’, I have a Beta enclosure of this type, the sides and top of the enclosure need to be removed for access.

Daily checks are easy, oil, water, and alternator belts, that is, via a small access cover.

Oil change, (with stb’d side removed) the filter is low on the starboard side, with care and a poly bag over the filter it is an awkward operation; if it is stiff a strap wrench may be necessary. Oil spills get into the base of the enclosure, a rag drawn back and forward on a bit of string under the engine, I use to clean up. Being a nice cream finish oil spills are obvious.

Fuel filter, (with stb,d side removed), easy as it is high up, a button on the top of the filter is easy to purge the fuel.

Air shift through the enclosure is essential to manage alternator temperature, flow in through the front through louvres, and out via a large hose (10cm) to atmosphere through port side of boat.

For access, the covers are heavy and a bit unwieldy, but after a bit of practice, it is manageable.

Finish, this is powder coated on steel, so good a durable.

Operation is very quiet, and all worth the effort, adds value. After 12 years the engine looks as new.

-

I agree with ‘aread2’, I have a Beta enclosure of this type, the sides and top of the enclosure need to be removed for access.

-

Commercial advertising is strictly not permitted anywhere on CWDF unless prior approval has been obtained by the Site Management

Is this not the case here?

-

This is clearly an advertising ‘stunt’ for this manufacturer.

Not applicable on this Forum?

-

-

Thanks Brian, grateful for the feedback.

I have Thermotop C, not sure if this is an analogue device?

-

This is a job which I need to do; getting a diagnostic connected to read 'Webasto Thermotop C diagnostics that is. Reluctant to order the kit without some confidence that it will work, and communicate.

Interested to see how this works.

-

Maybe, ‘performance related’…

-

Not a ‘volunteer’ I guess.

-

-

If the electrical distribution is competent, this is not possible.

-

1

1

-

-

As I understand the connection:

For a boat fitted with an isolation transformer, the secondary side of the transformer, neutral and earth should be connected together and bonded to the hull. The primary side, neutral and earth must not be connected to the hull. Isolating the boat from the shoreline.

If fitted with a galvanic isolator, the single earth connection between boat and shore supply must pass through the galvanic isolator.

-

4

4

-

Inverter motor washing machines

in Boat Equipment

Posted

A traditional motor for a washing machine has been a 'universal' motor with carbon brushes, speed control provided by a Thyristor Voltage controller. The result is reliable apart from brush replacement after some years and black dust inside the enclosure. The 'Inverter Motor' is a 3 phase device using a combination of permanent magnets an bars within the rotor, with no carbon brushes or commutator. Speed control provided by an 'Inverter', converting a single phase supply into a variable 3 phase supply frequency, for the 'speed' control and reverse.

Assuming this machine is for a boat with supply derived from an inverter, then it all gets a bit 'nebulous' as installations are created from a variety of line side components, making the single phase ac from a 12 DC, to be 'mashed about' by the drive system in the washing machine??

The are some success stories here which are useful, but there is a measure of luck getting a working combination; not much help I am afraid but I hope useful?