Split Pin

Member-

Posts

235 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Split Pin

-

The picture of the organ was taken at a Stourbrige Navigation Trust Bonded Warehouse open weekend, dont know which year but thay take place in October each year. The organ is sitting on the Stourbridge Canal Companies weighbridge in front of the original Canal Company buildings. I think that Harley came to the event and exhibited some paintings,posibly at the same time as the organ was there. Steven

-

Have been using this one from them for over 30 years in my Gardner https://www.aztecoils.co.uk/Topics/commercial_-_monogrades/hdx_30_api_secc_mon007.htm They used to have an agent in West Bromwich which is nearer to me, so able to collect it, about £45.00 for 20lts the last time I brought some, usually around 50% of Morris's for the same spec oil Can still get it through the new owners who also do other manufaturers.

-

Does it have its original engine? I remember that Albert Brookes purchased it from Claytons and fitted it into his first narrowboat named Glenfied in circa 1968/9. It could have been reunited by now. You no doubt remember the boat Pete as it was converted from a day boat at Bumblehole and kept at Windmill End may also have been at Valencia Wharf as Albert went on to work for the Allen Brothers Steve

-

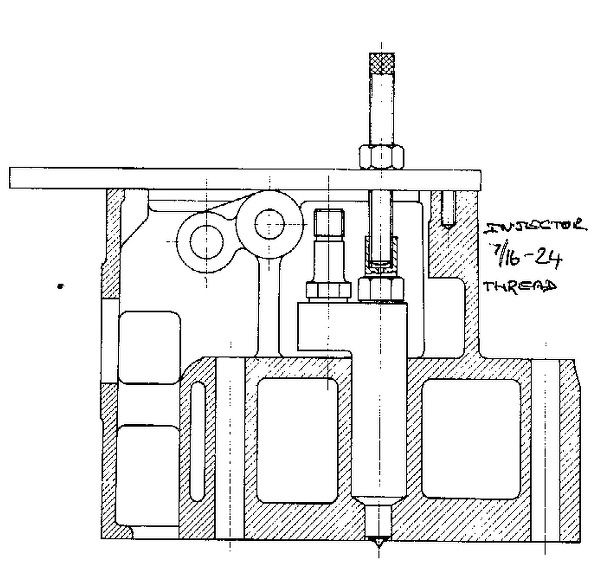

Gardners puller is a special bolt which screws into the leak off connection. as per picture and a flat bar which sits across the head I use a slide hammer directly into the same fitting. The thread is somewhat obscure as it is an Admiralty Thread 7/16 whit form x 24 TPI. As Mark says there is no copper washer just conical seat on the injecter nut against a taper in the head. They can get tight with carbon build up between the nozzle and the head Steve

-

This is the one you need assuming its the manifold to head one that is leaking https://gardnerspares.com/product/lxb-lw-exhaust-manifold-packing/ or https://gardnerspares.com/product/steel-exhaust-packing-rectangular/ if its the outlet one. Spanner size for the manifold clamp is 5/16" whitworth, thread size is 3/8" Whitworth, same for the outlet flange if it has the original pins Steve

-

Building bow well deck benches

Split Pin replied to blackrose's topic in Boat Building & Maintenance

Well mine not only has to help support the weight of two 13kg bottles plus part of the weight of the locker itself it also doubles as a step to get up on to the roof so has to support another 95kg when I step on it. As it is adjacent to the helm position it gets used may times a day to sit up onto the cabin, never had a problem the bolts coming loose -

Building bow well deck benches

Split Pin replied to blackrose's topic in Boat Building & Maintenance

My gas clocker is a five sided box with a wooden lid and is completely removable. it is bolted into the surounding steel work, some of the bolts being at about 1/3rd up from the bottom. Its been like that since the boat was built in the mid 1980's and has never been an issue Steve -

You would need to undo the pipe that exits left on the photograph and remove the adaptor union from the filter housing, the hole is then at the bottom of the tapped hole.The hole is 0.018" or 0.457mm in diameter so is not so easy to see. An easier way to check it is to remove the pipe and operate the lift pump manually fuel should flow out of the hole. In my experience if the hole is blocked then the engine will run for a short period then dies as the fuel has become aireated and the pump then needs bleeding again, so if your enine is running happily then its doubtfull that you have a problem

-

Hi have sent you a personal message Steve

-

I should be able to resleeve it for you and am nearer than N being just outside of Stourbridge PM me if you cannot find anyone nearer Steve

-

Only by a little bit 0.3 bar = 4.36112 PSI

-

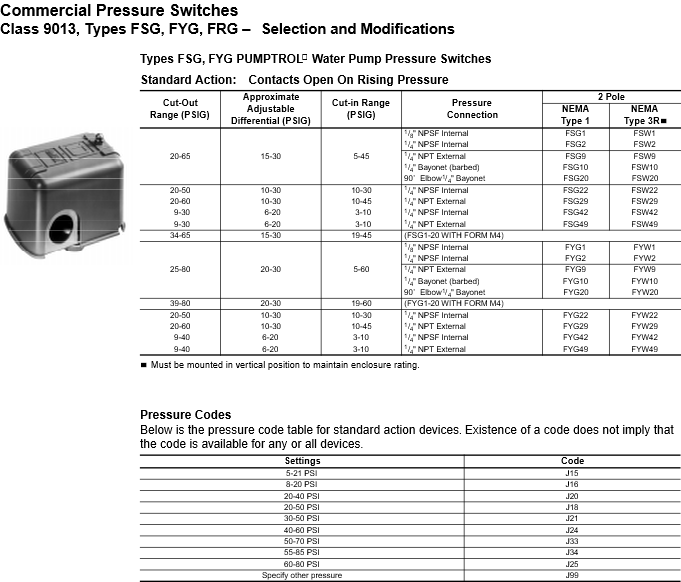

Looking at the datasheet the range is pretty much the same as the Square D one. Telemecanique own Square D Looking at the picture they have a very similar action but with an updated switch which resembles a motor contacter. As the Squre D Pumptrol switch has been around for at least 35 years to my knowledge maybe this will become its replacement. Steve

-

I would agree that the data sheets seem to make it difficult and it does depend on which one you find to look at Switches with either FSW2 or FSG2 as part of their number have a Cut in of 5-45 psi Differential adjustment of 15-30 psi Cut in Range 20-65 psi So setting the cut in at 25 minus the lowest differential gives you 10 psi cut in The J20 means that the Cut out pressure is within the 20-40 psi range as standard At least thats the way that I read it. You dont need to have an account as such with RS but you do need to have a user Id and the price that you see is what you pay. i.e no extra for postage Steve

-

https://uk.rs-online.com/web/p/pressure-switches/1242125/ This one should do the job it is within the range that you need but will need adjusting to match your needs. Steve

-

07817 142893 email iburnell@hotmail.com

-

20 If they all make it 10 Stationary Engines 9 Commercial Vehicles

- 16 replies

-

- l. gardner and sons

- etruria industrial museum

- (and 1 more)

-

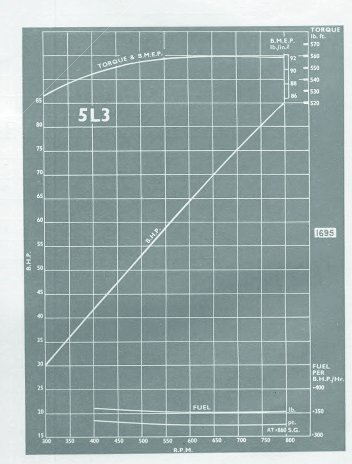

The books that I have relating to L3 engines list the Marine version as 900rpm max, Industrial versions were rated up to 1200rpm intermittent It would appear that the info given on the sales information is for max engine speed. I'm sure that it would run quite happily at full throttle all day long, although I can imagine that most would be run slightly below this for comfort. I don't have any experience of running an L3 (LW and L2 being my area of expertise) If you are on facebook you might try the Gardner Diesel Engine group for more information , I know that there are some members on there running L3's. Re the gearbox, 2UC boxes wont fit on L3 engines, (they are considerably different in size) It maybe that it has a 3UC type 2 which is causing the confusion. Steve

-

Fuel consumption in gallon and lbs along the bottom of the graph Looks to be around 3.6 Gall per hr if fully loaded at 900 rpm The gearbox will be a 3UC not a 2UC

-

In my experience if the bleed hole in the filter housing becomes blocked on lift pump engines, then the fuel gets aerated and after around 20 mins or so of running the engine cuts out and the pump need to be bleed before it will run again. Steve

-

Should you decide to remove the pump, the ease or not of refitting it depends on a couple of things, how much room do you have in front of the engine, you need to be able to remove the timing chain cover and be able to see the marks on the gears to get the initial gear mesh position right setting, I have had to do it using a mirror on at least 2 engines. Secondly do you have good access to the timing marks on the flywheel and do they match the setting for the speed at which the pump has been set?. I am just 5 miles away in Stourbridge and i can check out your pump (depending on when you want to do it). My number is in the front of the G.E.F newsletter or PM me if you would like me to look at it for you. Steve

-

Maybe, they are sometimes stamped on the top face between the pipe unions, most though are stamped on the side as on the left and wont be visible without taking one out. The one on the right started of as an "E" type. If they haven't been done then no its not really worth disturbing them. The absence of the "K" doesn't mean that they aren't to the later spec, if an Independent re conditioner has worked on them they may have used the later setting without marking them. As the rating plate doesn't have the engine number stamped on it would suggest that it has been worked on by an independent at some time in its life. Also the fact that the pump is stamped then it would seem logical that the sprayers would have been done at the same time.

-

There will be K stamped on the sprayer body, all sprayers that were reconditioned by the factory or a dealer were automatically modified. Its unlikely that yours haven't already been done. The change was made along with a modified piston design, and some different parts in the governor, this lead to a 10 % increase in power and smoother slow speed running,

-

The "K" refers to a change of specification which occurred in 1952 and indicates that the pump has been set to the later standard and should be used with sprayers that also meet the changed standard. The pump phasing was changed and the spring pressure for the sprayers was increased from 55lbs to 61.5 lbs. Previously sprayers were marked "E or E1" Gardner's only used the CAV Body, BPF pump elements, delivery valves and control rack etc. All the other parts were of Gardner manufacture and assembly. The pumps were built and calibrated in house. Gardner's originally made there own sprayers in house, the design changed very little from the first L2 "E" Type version (1929) to the latter type used in the LXC (1980's) Steve

-

In LW spares book 518.5 published in 1955, it shows the dual anvil rockers and the cam that moves the rocker to a second position to increase the tappet clearance, thus giving max compression as the valve would close earlier than normal, this would coincide with the lever being in the No 2 position. It was probably fitted to engines supplied with hand start only. As Martyn comments it was more common on L2'S. Its also worth remembering that the manuals are pretty much backwards compatible in that the information they contain applies with small variations back to 1931 Steve

-

Gardner Engine Forum was formed in 2001 by a group of enthusiasts all of whom were or still are narrowboat owners. In its infancy it was supported by Gardner themselves and later Gardner Parts Most of our members have narrowboats which by nature have the smaller engines fitted i.e 2-4Lw's and 2-4 L2's The forum grew out of some Rallys organized by one of the founder members and has been holding rallies every two years since, normally in the Midland and Manchester Area. We don't have many members in the South of the country. On the website under publications can be found PDF copies of all the newsletters published. We publish 2 newsletters per year so getting an answer to a query would take a long time. If you want quick answers then this forum or the Gardner Diesel engine face book page (nothing to do with the forum) is the best place to ask. We will be holding a rally this year to celebrate 150 years since the formation of L Gardner and Sons. It will take place on the 15th and 16th of September at Etruria. If you can make it you would be most welcome, you don't have to be a member to attend, we are a friendly bunch who are happy to pass on our collective knowledge Enjoy your engine, they are fine pieces of engineering. Andrew no doubt had sourced an L2 manual and left it with boat, if not pm me. As Athy commented , Graham Edges book is about as comprehensive a history of L Gardner and Sons, there is also "Gardner A product History over 125 Years by James J Francis", copies available from the Anson Engine Museum. A much smaller book as as the title says it is about the different types of engine. Steve (GEF Vice Chair and general goffer)