-

Posts

36 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Arf

-

Definitely one of Ted's. That's Atria - I know because its mine! Moored near Dutton a couple of years ago I think.

-

I've had a boat with a tug deck for about 8 years and haven't really had any of those problems. Provided the deck is long enough and you've got a reasonable amount of headroom inside they're amazing for a bed - ours has a permanent king size bed underneath and just three and a half feet of headroom, so I can sit up in bed despite being 6'3. This also means you don't have to faff about with folding things up or constantly making and unmaking the bed. My experience of tugs has been that they normally sit a bit lower in the water, so usually have a lower air draught too. This means provided you have a suitable chair you shouldn't have the same problems with vegetation as the other boats on the cut have already torn it off with their higher cabins! We have a pair of low folding deck chairs that are ideal for this and dead comfy. I love an engine room too - much nicer to sit on the floor while working on it rather than the upside down contortion fest in the stern engine bay on our old boat.

-

I think they were built down on the southern bit of the Shroppie near Shebdon. Posting this from Atria. Moored in Huddersfield until the end of the week, but continuously cruise and have taken her all over the place. Had no idea there were so many of Ted's boats in Yorkshire! Last one I saw out and about was Lizard on the Shropshire Union, about 3 years ago now.

-

Fazeley, Coventry, Trent & Mersey, River Soar, Leicester - what's this like?

Arf replied to bpboat's topic in General Boating

Did a similar trip a couple of years ago - the summit of the GU, Market Harborough Arm and (especially) Welford Arm were the best bits. If you've not already done it and have time, a there and back detour down the Cov and up to the end of the Ashby is well worth it too. -

Did we have this one yet? I think you'd have to be brave, given how long this has been since it's been out of the water.. 1932 Yarwoods short boat

-

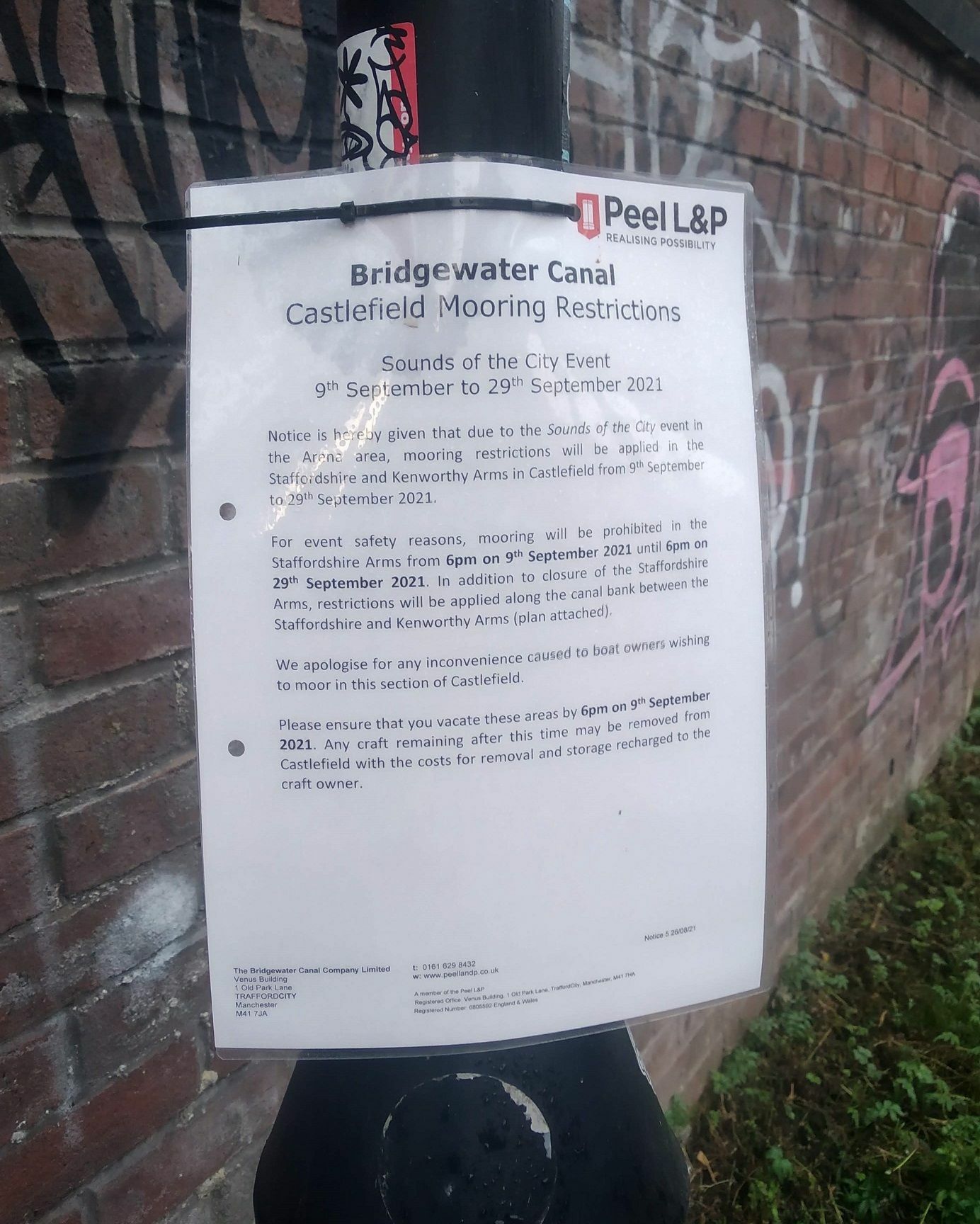

In usual Peel style, this notice hasn't gone out on their website or to CRT. The Staffordshire and Kenworthy Arms (basically the only remaining visitor moorings in Castlefield) are closed from 9 to 29 September 2021 because they've put a big stage over the top of them. So any CRT boaters coming through this way basically have nowhere to stop - the other arms were full this morning and are occupied by permanent moorings now. Just as well there are loads of easy to access safe places to stop nearby...

-

Great video and great dog! Looks like its come on a bit since I last walked down there a couple of years ago. I think quite a lot of vegetation has been cleared from the canal bed since then.

-

Two jobs and a big hobby - can boat life work?

Arf replied to Captain Beefheart's topic in Living Afloat

I continuously cruised in the North West for about six years while doing a 9-5 in Manchester, before starting working from home about two years ago. Living on, maintaining a boat and moving it was mostly a pleasure. Commuting wasn't, but never is - a decent folding bike and a willingness to cycle a fair distance to the nearest train station meant I had a very large cruising range. On reflection I think the essential things for me were: A boat in good condition mechanically and hull-wise as a minimum! The other stuff is important but not as much. Getting help from someone who knows what they're looking is a idea, as is the willingness to walk away from a bad survey (much less painful to lose the survey money than have a lemon on your hands for years). Actually enjoying boating and canals. If we didn't love it, the commute would have killed it. Can't think of anyone I've known living aboard to save cash who's stuck it out for long. As with anyone on a boat, being tolerant of the fact that boating is always inconvenient compared to living in a house. There's a degree of forward planning and organisation needed. Also being prepared to have less devices helps - energy demand reduction beats running an engine/genny all day. Can't think of many better places to be for painting and photography. Just to add though - due to the depth, few spots to moor and water issues I think the Huddersfield Narrow would be very very hard to CC on. -

Link is here: http://publicaccess.staffsmoorlands.gov.uk/portal/servlets/ApplicationSearchServlet?PKID=142566 Had a look and sounds like it would be complete blight on my favourite section of canal . The development would also obliterate the remains of the Uttoxeter Canal in Froghall that lie beyond the basin, ending any possibility of restoring any further part of it.

-

Thanks for your help. The boat hasn't had an accumulator since it was built about 13 years ago, but I'll give this a try. If nothing else it should take the stress off the pump.

-

I have been experiencing an odd issue with my Morco D61E unit which has developed over the last month. When turned up to the highest end of the temperature gauge with any hot outlet open, it causes the water pump to cycle rapidly. This problem disappears and flows just like the cold outlets if the temperature is turned down - suggesting its not a furred up heat exchanger. The issue happens whether the pilot is lit or not, suggesting its not an issue with trapped air. I've read previous threads on similar issues and come to the following two conclusions - please could someone let me know if these are reasonable? As the heater is triggered by a flow differential, the water pump is no longer providing an adequate amount of flow when the burners are on full. Do water pumps producing a decreasing flow as they age? Its fine for everything else. OR: The water control assembly has a fault. Would a replacement or repaired assembly likely fix the problem? Does anyone know if this is separate to the gas bits of the heater, so I could replace this myself? The water pump is a Jabsco par max 2.9, which we've had for about three years now. I don't have an accumulator, even though I know I probably should. Thanks

-

Provided its not too far, I think you could moor without too many worries past the aqueduct or after Croxton flash to the north. Its nice and deep there and should be far enough out.

-

An odd one, but there's also a 24 hour contactless launderette in a petrol station forecourt at Endon, fairly close to the services before hazlehurst

-

This is exactly what I've done both times. Maintaining that kind of pressure seems to have given it a decent key. Might be that epoxies without coal tar are a bit less resilient to a wire cup brush.

-

I went through this process, with exactly the same epidac epoxy last year: I applied Jotun 87 after a (very powerful) jetwash at Northwich dry dock and scratching up the original coating with a wire cup brush on an angle grinder. You may find, like me, very little comes off when its dry dock time. Bar the sections I've donated from to the network from the rubbing strakes, it appears to have held up well in the last 12 months. From memory, the main things I had to watch for were making sure I had enough time in dry dock for a full cure, getting the right mixing ratios (check the technical data sheet) and being quick enough to apply it within the 'pot life'.

-

Anyone been through Froghall Tunnel... looks tight!?

Arf replied to larrysanders's topic in General Boating

Oh and I always drop it out of gear then slow to a stop on leaving the tunnel towards Froghall. Its very shallow and even with our 54' boat, I can never make the tight corner on first attempt. Battered piling there suggests I'm not the only one who's had this problem ?? -

Anyone been through Froghall Tunnel... looks tight!?

Arf replied to larrysanders's topic in General Boating

We go through regularly with a replica BCN tug style boat. With a fullish water tank we're about five foot to top of handrails and five foot across the top - I think this is what the crt sign says the limit is, but we slip through really easily with no problems. Tend to find that it's historic boats, replicas and 70s / 80s boats in the basin. -

Thanks for the advice, some food for thought. Sounds like it's worth doing the locker first to improve my technique.

-

That's what I was hoping to hear. I'm planning on doing much the same with the gas locker as the vents can let a bit of water in with a full water tank. Think I can live with a finish that isn't 100% smooth as the matt topcoat should hide the worst - its there to be walked over and have stuff put on it anyway.

-

Hello everyone. Hopefully an easy question to answer. I've got to repaint my roof this year as rust has broken through in a number of areas. Given the success we've had with the use of two pack epoxy on the hull, is there any reason not to use an appropriately coloured 2 pack epoxy primer on areas of the roof? We'd then paint over this raddle red / epifanes multiforte or similar. There are a number of areas on the roof where water can collect temporarily, and I was hoping this might resist immersion for short periods.

-

I found myself in a similar situation earlier this year - overcoating a coal tar epoxy with something else. I spoke to Jotun and International and received the response below. I didn't as regarding moisture tolerance unfortunately. I went for Jotun 87 in the end. You can get it in 'winter grade', because the normal 87 takes more than a week to cure. Full thread is here:

-

Pretty good news on the whole from Jotun and International. Both people I spoke to confirmed that bleeding was to be expected. but that provided there was an adequate amount of surface abrasion of the original coal tar epoxy the jotamastic 87 or interzone 954 coatings should adhere ok. Both said that the bleeding should be an aesthetic issue only. This doesn't bother me too much, and the discolouration should apparently be quite limited given it will be against the black of the coating. I was told an aluminium rich primer would seal the tar better.

-

Ace. Will report back in this thread once I get a chance to ring them.

-

It's may be a major headache for many - at least I know what the existing coating is! Haven'thad a chance to get onto a manufacturer yet, just suppliers. But, International intertuf 262 looks like it might be an option to seal the coal tar epoxy before putting the next stuff on. The datasheet for this product says it's suitable for spot repair and 'upgrading' of substrates including coal tar epoxy, and then needs coating with intergard 263, a tiecoat. Not a cheap option and haven't found a UK supplier yet, but has to be better than paying to blast it all off and start over