-

Posts

791 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Mike Adams

-

nautic boiler extra heating coil

Mike Adams replied to Mike Adams's topic in Boat Building & Maintenance

The 'hole' through which the unit needs to fit is only 39mm. Maybe a 12mm one, if you can get it would fit. -

You can always measure the resistance between B- and the case. Maybe it is an insulated return machine in which case B- will take the full current so you will need a cable similar to B+. I dont see why you can't just ground it to the case if you don't need an insulated return alternator.

- 31 replies

-

- alternater

- prestolite

-

(and 1 more)

Tagged with:

-

Clearly by the size of the connection (B-) it is not designed to take the full alternator current or it would be the same size as B+. Maybe it should be connected to the -ve of the battery as part of the sense circuit. Normally the hull, engine and the negative terminal should be at the same potential so connecting to either one shouldn't make any difference. Some of these Isuzu connections are poor so check the negative connections from the battery to the engine and the black wire from the harness to the engine. The multipin plug can also cause problems. Hope this helps.

- 31 replies

-

- alternater

- prestolite

-

(and 1 more)

Tagged with:

-

nautic boiler extra heating coil

Mike Adams replied to Mike Adams's topic in Boat Building & Maintenance

I've decided I am going to have a go at fabricating one myself using 4 lengths of 15mm pipe 20 inches long to fill the full length of the horizonal cylinder. I will make up a brass boss with a 1 1/4" inch thread at one end and a plain one at the other end with cross drillings in both bosses to get a continuous loop and solder the pipes into each boss. I will post a picture when I've made it. Cheers! -

nautic boiler extra heating coil

Mike Adams replied to Mike Adams's topic in Boat Building & Maintenance

Thanks TD looks suitable but maybe it is only a couple of these at £3.95 from screwfix? -

nautic boiler extra heating coil

Mike Adams replied to Mike Adams's topic in Boat Building & Maintenance

Thanks. The problem is that the hole with the heater in is only 1" 1/4 BSP much smaller than the domestic ones and I am not sure of the minimum bend radius for 10mm pipe to make a coil. Anything smaller probably wouldn't allow sufficient flow. I am thinking of 6 lengths or however many I can fit in of 10mm into a brass boss at either end with drillings to make a continuous coil. I could thread one end to screw into the tank. I need a few lockdown projects! -

I have a 40 litre nautic boiler with only one heating coil. It has an immersion heater that dosen't work and I have never used. Rather than change the calorifier for one with two heating elements so I can connect up the webasto that does the central heating I was thinking of either fabricating a coil that could be inserted in place of the electric heating element or buying one. I seem to have a vague recollection that these were available in some form but I can't find any. Anyone done this or similar?

-

Isuzu 35/42 - priming or bleeding

Mike Adams replied to Keeping Up's topic in Boat Building & Maintenance

You need one of these on that engine. Plenty on ebay. -

Removing Calorifier - Engine cooling question...

Mike Adams replied to WillCful's topic in Boat Equipment

I think if you disconnect the pipes from the calorifier you should put a shut off valve in the line. I believe in some engines the low resistance path between the 'heater' take off pipes can cause over heating or over cooling. I don't know which engine you have but it shouldn't do any harm to stop the flow through the pipes. -

Base Plate Rust Treatment

Mike Adams replied to TheSaintlyOne's topic in Boat Building & Maintenance

That looks like a lot of serious corrosion unless the baseplate is a decent thickness (8 -10mm) to start with. You need to know how much metal you have left otherwise you could end up with some holes. The only way to clean this up is with an electric or air powered chisel or needle gun and that is going to find any thin bits so best not to do it in the water! Has the boat had a survey recently? Even that may not give a good indication as the scale could give a false reading. If the boat is out of the water you can drill a few test holes and weld them up later of if in the water try an ultra sonic thickness meter on sample areas after grinding back to metal. Good luck -

Base Plate Rust Treatment

Mike Adams replied to TheSaintlyOne's topic in Boat Building & Maintenance

Unless you can get the metal to near shotblasted condition I don't think any paint system will work in the long term. I used about 30 litres of Anti Roestvet Grease(anti rust grease, after wire brushing and a nominal coat of red oxide. It is used by heating it up and pooring it into the bilge leaving about a thickness of 3mm, it goes hard a bit like waxoil. I guess it prevents oxygen getting to the metal. You can't use it where you have oily water but in the main part of the boat it seems fine. If you get a water leak it just runs on top of it so you can collect/evaporate it. You need to stop the water running through the boat. Was about £100 for 18Kg. After a couple of years no sign of any rust -

Index no on the photo 69054

-

OK so how many boats on the system are houseboats according to this definition? If you live aboard for 13 days and then move for one day or less then the predominant use must be not for navigation therefore it must be a houseboat.

-

Building Regulations refer to a 'dwelling'. I know this applies to caravans not sure about houseboats

-

The BMET course is focused at Electrical engineers which I guess the OP is not. All qualified electricians undertake a long apprenticeship/training and work on low voltage(240) in special locations(i.e. boats) may or not be included in the normal training. Same for Gas/LPG. With so many boats now being used as live aboards and the introduction of complex 240v systems on boats there is huge potential for disaster. Anyone working on other peoples boats on LPG or Electrical installations must be properly certificated and have full PLI in my opinion. I wish the OP luck.

-

I think there are some variations on the Z model(this is why I used the C version) some of which are controlled by the vehicle ECU. You need to find out if it has a manufacturers plate such as BMW or land rover. some are more difficult to use. I am no expert but picked this up. It may not be true of couse!

-

I had one of these twin tubs and mine had two separate motors, one for the washer and one for the spinner. I never tried using them both at once but it worked fine on a 500W 24v inverter using the spin drier after the washer. The current will be large running from 12v say 50A so you need the battery close to the inverter or with large diameter cables otherwise the voltage drop to the inverter will make it shut down. Easy to measure with a multimeter.

-

I was just thinking about when we leave the EU and importing a boat what the charges might be - I remember importing a car from Japan and the Import Duties and VAT were very significant and might well outwiegh the saving by purchasing in Holland. In about 1987 I went looking for barges/ boats in Holland, Germany and France. The cheaper ones always had some drawback i.e too deep , horrible fit out etc. In the end I bought a GRP boat in the UK and had ten happy years cruisng around the continent. I think it must be an expensive nightmare trying to find a mooring for a dutch barge in the UK and in my last couple of years in France/Germany anything over 15m is often difficult to find a mooring while cruising. If I were to do it again I would probably go for ex hire GRP cruiser.

-

What I forgot to mention was of course that the engine was moved to the rear underdeck during Jason's ownership/fitout. Some years before that the bare hull was lying at Norwood Top Lock and I tried to buy it from the owner without success, the engine wasn't present but I was told there was one for it. I assume this was the one that went into Iona. So the FR3 would have been the last engine in the original engine room. Positioning the smaller ford engine under the rear deck made most of the boats usable accommodation.

-

I am sure the engine put into White Heather by Jason was a lowline Ford 6D. When I swapped the boat for Coronis that was still in it but I took that out because it was blelching smoke and leaking oil everywhere and fitted a Dorman 3LB. Unfortunately that increased the draught too much so after an attempted trip up the oxford canal I took it out and installed the Toyota engine which it still has today. That was supposed to be a temporary solution but since it has run for some 20 years now with only oil and filter changes I haven't done anything about changing it out. That makes 6 engines in 88 years if it had a Petter at some stage.!

-

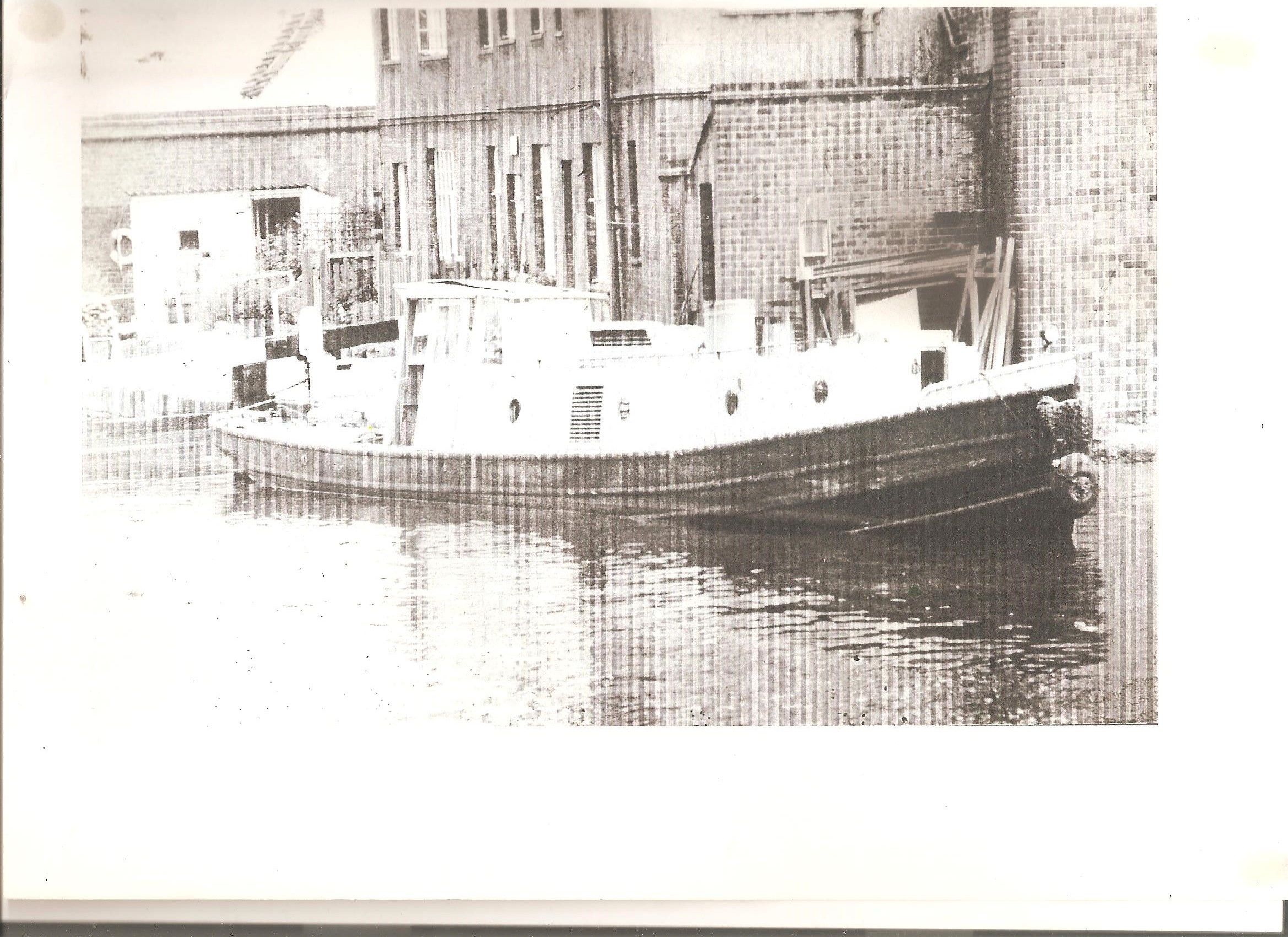

Thanks Pete. I have never seen this picture before and at 1967 it probably predates the one below which shows the boat, above Camden lock I think, and you can just make out the BW wave logo on the side. It also shows the very large cut out ventilator on the port side. I thought the FR3M was a water cooled engine so I am not sure if there was another engine fitted between the Robey and the FR3. The first photo I posted shows the boat with what looks like the original engine and funnel removed and judging by the waterline quite empty but still with the Marylebone council shed wheelhouse that was fitted to both White Heather and Tyburn (ex W and B Birmigham). Maybe it was during a BTW refit. When I first can about the boat in the 1970's it was derilict at the top of Norwood locks when it had been disposed of by BW and without engine.

-

Now I have some forced time on my hands I am trying to put together as much history as I can on my GU Paddington Arm canal tug 'White Heather' . I remember ther was a photo in an old Waterways World(when it was in black and white) showing a view of Hanwell Yard(Norwood Top) where the boat was based with White Heather in what appeared to be BTC or BTW colours of blue with yellow coach lines and a BTW logo on the funnel. If anyone is browsing through old WW's please let me know if they find it. Unfortunately I threw all mine out some years ago. Here is picture of the boat when it was rather sad and without its funnel.

-

Making a rev counter - how hard can it be?!

Mike Adams replied to tommylad's topic in Vintage Engine Forum

Try a ISSPRO R8585M programmable tachometer. Works on the alternator or magnet on flywheel. -

You will be fine. I went around the Paddington Arm with 8'6" air draught and drawing 4'6".

-

This post cannot be displayed because it is in a forum which requires at least 10 posts to view.