-

Posts

53 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

United Kingdom

-

Occupation

Mechanical Engineer

-

Boat Name

The Whippet

-

Boat Location

Shardlow

Recent Profile Visitors

1,806 profile views

tommylad's Achievements

Engager (3/12)

8

Reputation

-

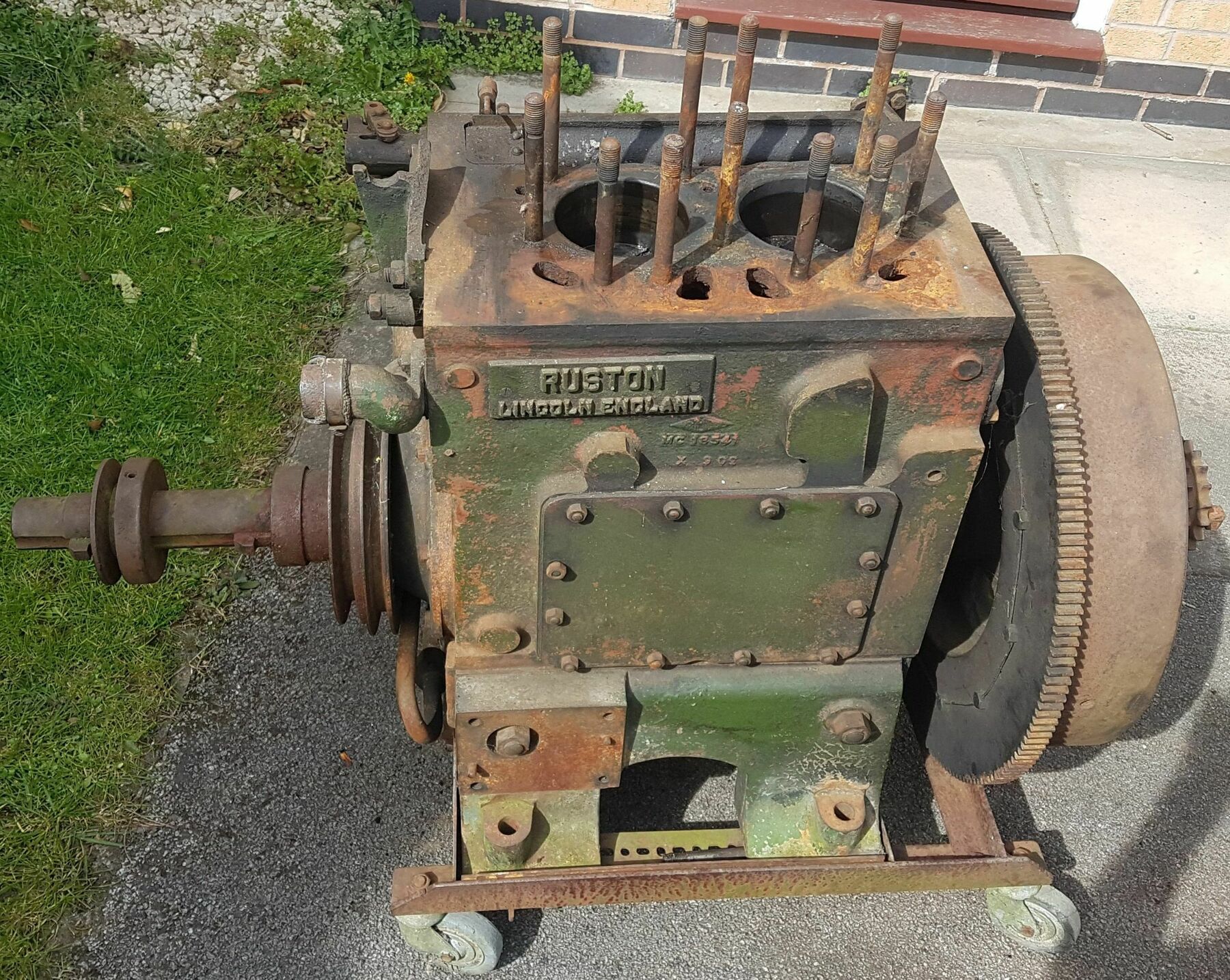

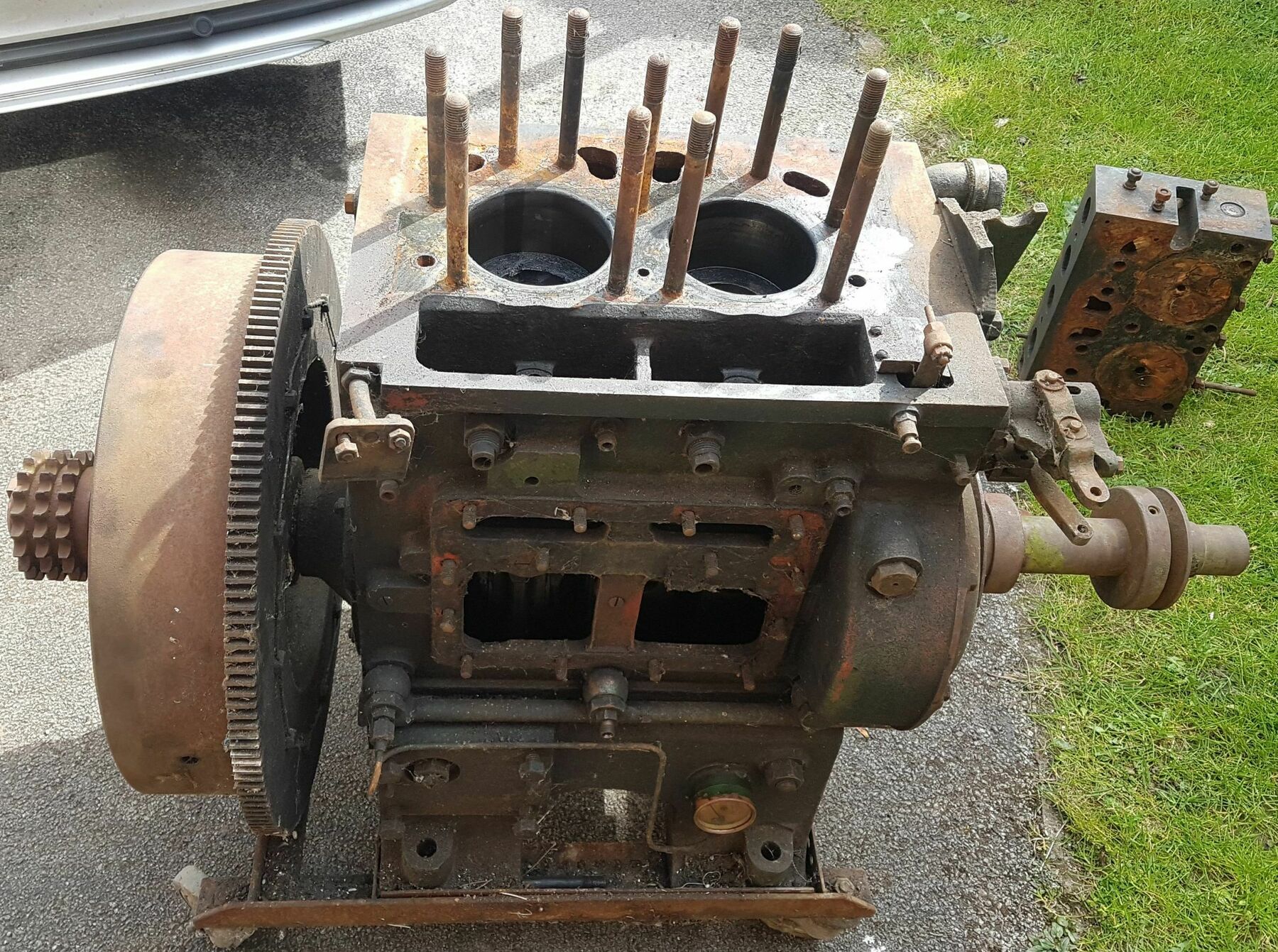

Hi, I have a Lincoln Ruston & Hornsby 2 VSH for sale. It was purchased around 40 years ago and came from a crane. It appears to have been sadly neglected when we bought it, as the bottom end was full of sludge. The rocker box has been smashed where someone ripped off the brass plaque. This could be patched over and used again. One of the lifting eyes has also been broken. I've not had the engine running, but I have had the head off. This is now refitted. The engine comes with fuel pumps and injectors, starting handle, thermostat housing, fuel filter body, and starter motor clamp. It is on a makeshift trolley. It is available for collection from DE24 5AE. You will need your own lifting gear unfortunately as I don't have suitable lifting gear. Price £150

-

Hi, I have 1 off, boxed, genuine Ruston & Hornsby fuel injector for the VSH engine for sale. Part number: VSH-111E. The box is opened, but the injector is still in its protective wax coating and wrapped in oiled paper. The box states 'Aug 1952' on it. This was purchased with a 2VSH around 40 years ago and has been dry stored since. Price £300. I can post or collection from DE24 5AE is welcome.

-

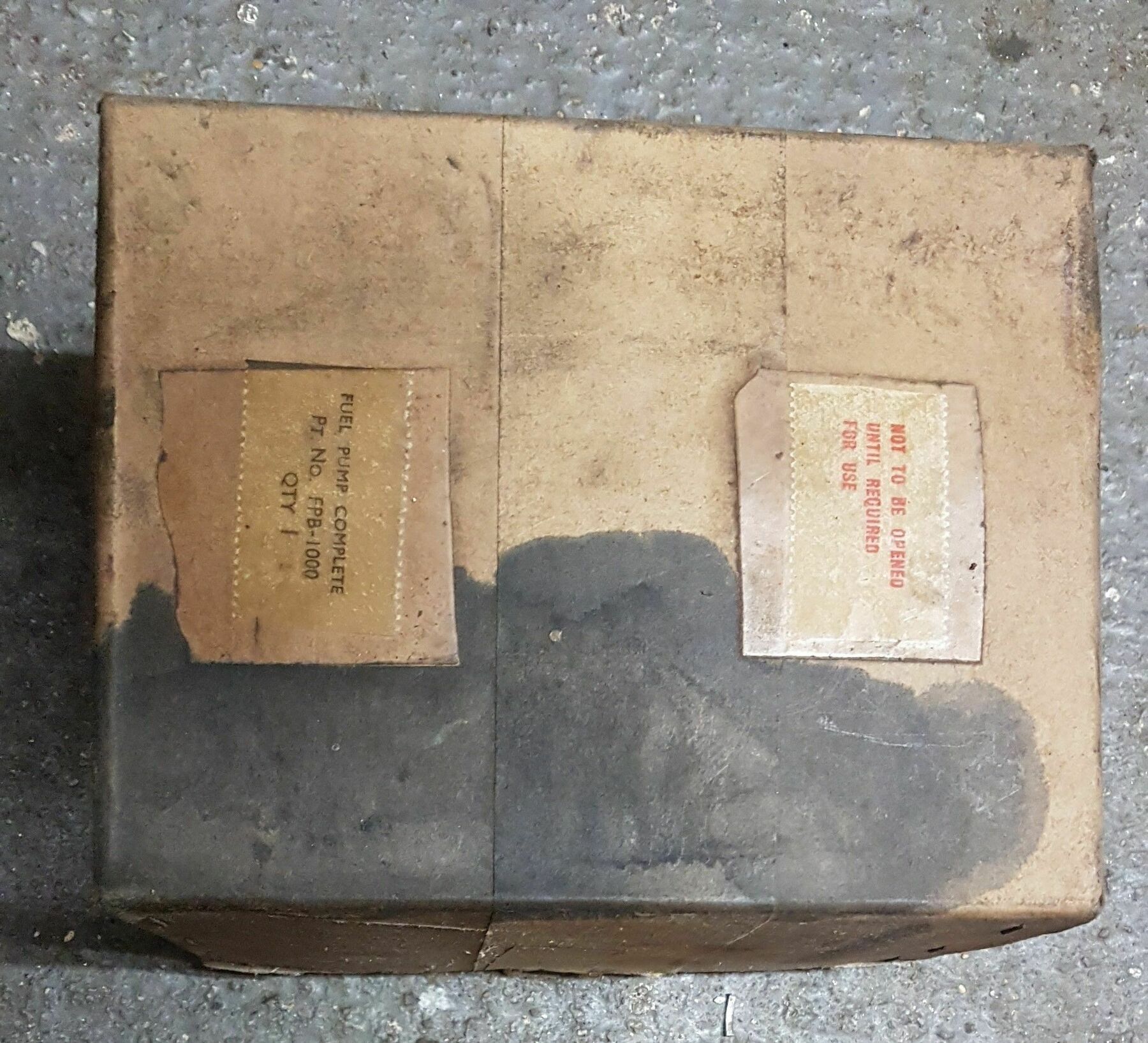

Hi, I have 2 off, boxed genuine Ruston & Hornsby fuel injection pumps for the VSH engine for sale, Part number on packaging: FPB-1000. Part number on pumps: FPBA1000B The boxes are opened, but the parts are still in their protective wax coating and wrapped in oiled paper. One of the boxes states '1952' and the two boxes are identical. These were purchased with a 2VSH around 40 years ago and have been dry stored since. Price £500 each. I can post or collection from DE24 5AE is welcome.

-

Yes, all sounds familiar! And yes, it's just not funny how annoying it is!!

-

It's a marine auxiliary engine (1962) - came from an isle of mann ferry (was used for pumping water for washing the decks), so dry sump, water cooled silencer, even lloyds stamped, but with the industrial crank and no gearbox. Odd to think it's been in the narrowboat for longer than it was in the ferry! Interesting comment. Are we perhaps causing damage to our irreplaceable pumps/injectors by running modern fuels in them? Has anyone else got experience/knowledge of additives which might help?

-

Just thought I'd share my experiences of finally sorting the hunting problem my engine has suffered from when hot at idle. It used to idle beautifully around 30 years ago, but gradually started hunting as the years have gone by. I gather this is a problem for quite a few JPs - and I know some on this forum have given very useful advice on it. I'd always assumed it was because of worn bearings in the governor, so when I rebuilt it 3 years back I was surprised to find the governor in spot-on condition. I did replace the tension spring and clean out & re-lube the bearings on the bell crank, but surprise surprise when the job was finished the hunting was still present. More recently, I've checked some of the setup of my fuel pump, and whilst in there, decided to oil some moving parts which I understood should be lubricated by diesel, but I thought why not? As I oiled the rack and plungers, I noticed that the movement of the rack did free up a little, and to my great delight I've found that the hunting is now gone! I'm so pleased to have my metronomic grand father clock back at last!! I'd encourage anyone with the same issue to not fear going into the pump to try this fix, as it's very easy. I'd always been reticent to open up the pump but if you're careful with cleanliness then you really shouldn't fear taking the inspection cover off the side of the pump and squirting a bit of oil around in there. I used 20 grade mineral oil. If you have a very compact screwdriver the cover can probably be taken off with the pump in situ, but I removed my pump to do the other checks, which does make access easier.

-

I'd try and avoid any disassembly to start with, just oil the threads which are exposed when they're screwed out. If they're coked up it might be an idea to wire brush them before oiling. Mine is smokier on low compression when on light load too.

-

Sounds likely that it's carbon build up. They do need screwing in quite tightly even when clean & oiled (both hands). You could try oiling the threads and giving them some 'exercise' which should sort it I'd expect. If it comes to it, removing them just needs a big adjustable in my experience

-

I think this could well be the candidate for the oil in the exhaust. In my experience by the time the oil can overflow down the push rod tubes it's already above the valve guides, so oil can track down the exhaust valve stem and then onwards to your hair/clothes/wine glass etc 😛 If you've already reduced oiling to a minimum it might be worth waiting a while to see if this fixes the problem

-

Impressive that the as-cast surface is that good, both wrt surface finish and geometrical accuracy

-

Ah I see - sounds obvious when you explain it! Interesting how one CNC machine can do the work of so many customized ones

-

No, I guess you really need a CMM for properly checking it Yes, I'm baffled as to how they machined pistons before CNC machines?

-

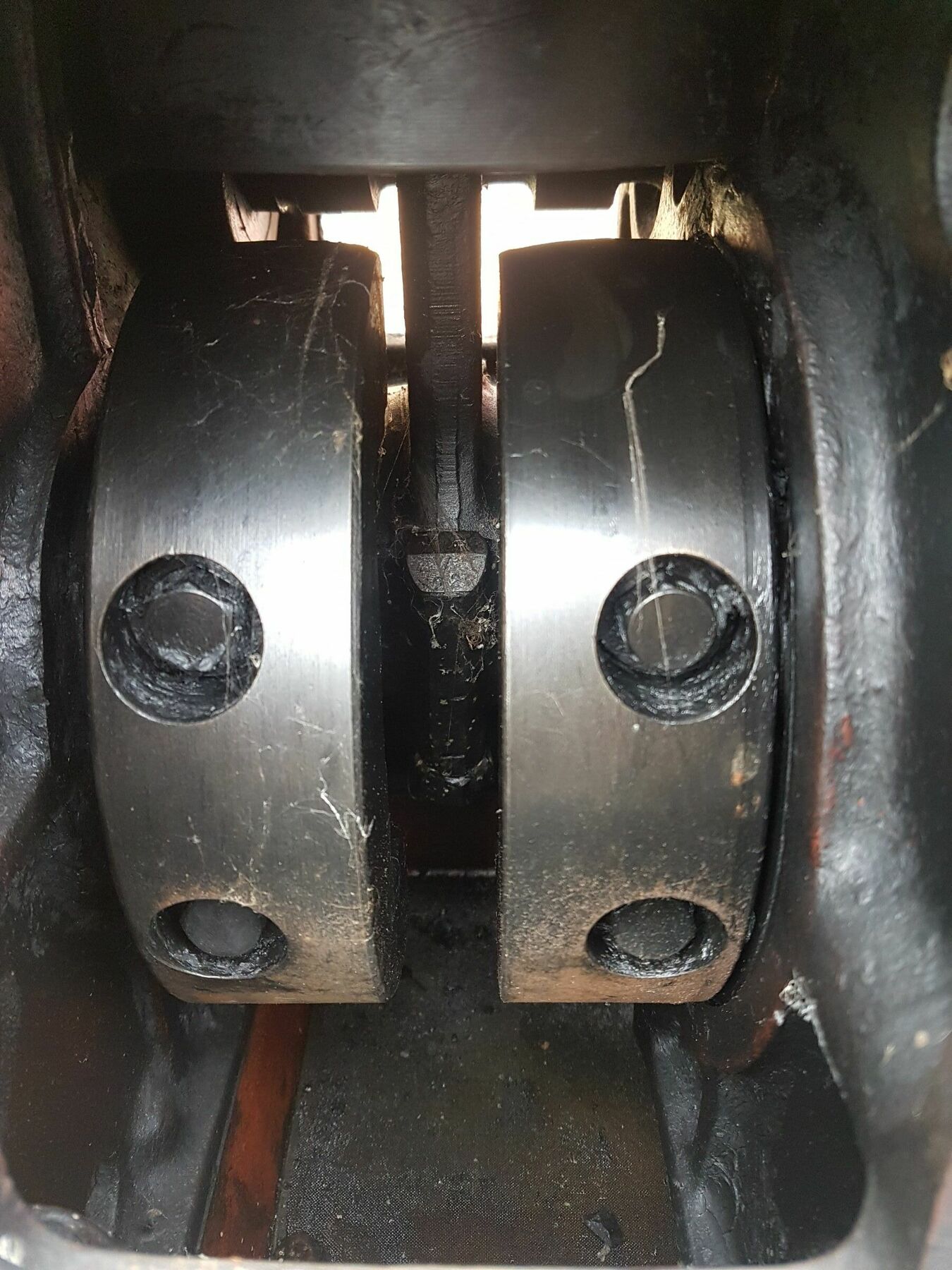

Many thanks for this BEngo - I did check and had (and still have) the 2 thou nip stated in the manual. Would be good to have cylindricity checked wouldn't it - although I guess it must be very close anyway else the bearing would've been tight when fitted.

-

Yes thanks! Lots of lovely engines lying around! I particularly liked the NEW 6 cyl Riley blocks they're machining up! I've left the big end with them - Martin was very relaxed about the job, apparently the smaller the bearing the harder it is to remetal, so a JP one should be a doddle! Many thanks BEngo, but as above I've taken it to CCE, Cheers, Tom

-

Cheers Richard, I'll give them a try too