-

Posts

667 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Giant

-

STARTED PAINTING - HELP PLEASE!!

Giant replied to Fozzi in Lancashire's topic in Boat Building & Maintenance

Regular ones will fall to bits with any solvent based paint. We've been using these ones from Toolstation for alkyd and xylene paints: https://www.toolstation.com/shop/p49410?table=no -

Those Baofeng radios will let you transmit and receive all over 136 to 174 MHz with various parameters. Mostly used for ham VHF/UHF and PMR frequencies, but I've heard them being used for marine VHF and they work OK. They don't actually have the appropriate certifications to be used on the marine band though, and it wouldn't surprise me if the emissions and performance are well short of spec.

-

How to get something wider than the lock through one

Giant replied to zenataomm's topic in General Boating

Works for bridges too! -

Boatlessness is really just a symptom of wider problems. We need to get tough on the causes of boatlessness if we are truly to help its victims. ...more moorings available would be a good start.

-

Builder's plates from John Harker Ltd, Knottingley

Giant replied to Giant's topic in History & Heritage

Thanks to Andy Horn, I now have an actual photo of a post-war Harkers plate to work from - this one on the tanker BROCADALE H, built 1961. It looks like they were engraved into thin sheet with a white infill, rather than being the thick cast brass affairs I'd been imagining from the rubbing of MARTINDALE H's plate. So I have revised my plans - I'm going to engrave the design into some 2mm brass sheet, on a big CNC router table I've recently got fixed up. Looking at the photo, I wonder if the original was bronze rather than brass, but I could believe either. Any guesses? -

Thanks, I'd like to have a look at that intro first, but having some trouble as Google seems to have indexed only an earlier version that I guess you've since removed. I've now found http://www.academia.edu/33845534/To_Rescue_Our_Soldiers_Dunkirk_Evac_Paper_v._4.8.pdf but it says you've not uploaded it yet.

-

Thanks for all this interesting info. I'd be interested to read your paper - where will we find it?

-

No narrowboats it seems, but one inland working barge that did go to to Dunkirk was the Humber Keel Gainsborough Trader. It was the only keel to go I think - the RN were not taking vessels from as far afield as Yorkshire, but G.T. had been sold to a firm on the Thames some years previously. The current owners took her back over for the 75th anniversary in 2015 - the papers ran this picture of her leaving Dover. Several Thames sailing barges made the trip but few returned. One that did was Tollesbury which is owned by some friends of ours, I told its story in the last thread.

-

You can get steel plate supplied already shot blasted and epoxy primed. We did this for our overplating and it meant there was much less prep to do before painting, after all the welding was finished. Obviously it will cost more than plate straight out of the mill, but might be worth it in time & problems saved later.

-

It all started with a post, the making of a skylight

Giant replied to bigcol's topic in Boat Building & Maintenance

The panes in ours are bedded in with some sort of black silicone and it's show no signs of UV damage after several years. I pondered removing the panes and redoing the bedding when refinishing it but decided it was working fine so didn't touch it! -

It all started with a post, the making of a skylight

Giant replied to bigcol's topic in Boat Building & Maintenance

Now keep on top of looking after the varnish on it Col. Every couple of years rub it down a bit and put on a new coat. We didn't and I recently had to take ours back to bare wood to refinish it from scratch. Looks nice again now but took bloody ages! -

Well if that's your approach, feel free to let us know next time you dump it somewhere

-

Do we get the backstory to this thread?

-

Would be on the Rother Navigation, closed in 1888. Ran from Midhurst down to the junction with the Arun, just below the southern end of the Wey & Arun canal. http://www.coultershaw.co.uk/the-rother-navigation/

-

Someone over on the DBA forums was reporting good results in France from using a small water pump to bring water up from the canal/river and running it over the roof of their barge. I would be tempted to try it on ours, but the water here is dirty and brackish. On a cleaner inland river I'd try it. Maybe with a long pipe down the centreline and holes drilled in the sides at intervals.

-

There isn't an "alternative modern/spec for CC grades". You just carry on buying CC grade. There are plenty of suppliers still offering it. We get ours from Morris Lubricants.

-

The SE spec refers to its use for petrol engines, so separate from the CC spec for diesel. See this page which lists the S and C series categories: http://www.oilspecifications.org/api_eolcs.php

-

I think you mean IPx5 or IPx6. The first digit is against solids, the second one is the liquid protection rating. As to your question, the level 4 liquid test is a gentle spray for a few minutes. Personally I find the level 5 rating is a better predictor for whether something will stand up to hours of heavy rain, especially for something where runoff water can end up running continuously over it.

-

Depends, is it actually suitably rated for outdoor use? There are a lot of 16A appliance inlets kicking around that are only actually rated IP44 or so. That's the level of waterproofing you'd be allowed in a domestic bathroom as long as it's not actually too near the bath; not something that's really designed to be outside in the pissing rain. For outdoor use I'd normally want a rating of IP65 on something, but people can and do go with less. This is a random IP44 rated appliance inlet: This is an IP65 rated one from the same supplier; to achieve that rating it needs to be used with an inline socket that has the matching flange for the sealing ring. Obviously few boats bother, but that doesn't change the answer to your question, which may just be: "because it wasn't designed to keep water out in all conditions".

-

I don't know what was actually standard on the Sea Otters, but the reasons for earth bonding the AC system and fitting a GI or IT are just as valid for aluminium as for steel. Earth bonding is for safety - if there is no earth bond, and something shorts to the hull, then the hull is live, and nothing will detect this fault. With an earth bond, a short to the hull will return a current to earth and trip an RCD. The same considerations would apply to any conductive hull material. A GI or IT is to protect the hull against galvanic corrosion when connected to shore power. The galvanic voltages are slightly different for aluminium (-0.8 to -1.0V) versus mild steel (-0.6 to -0.7V) but the issues are the same.

-

! Hope you manage to sort it.

-

It's tidal up to Wylam and managed by the Port of Tyne. No charges for visiting pleasure craft for up to 14 days, or for vessels launched and recovered each day.

-

We have four coats of Hempel 15130 on our hull. It was no problem to apply DIY with big rollers. Be aware that it does quickly turn from a gloss black to a chalky grey. If you want a gloss finish you'd need to apply some top coat.

-

What have you fettled for the boat today?

Giant replied to Captain Fizz's topic in Boat Building & Maintenance

No, Sikkens Cetol. A base coat of HLS Plus and then two top coats of Filter 7. -

What have you fettled for the boat today?

Giant replied to Captain Fizz's topic in Boat Building & Maintenance

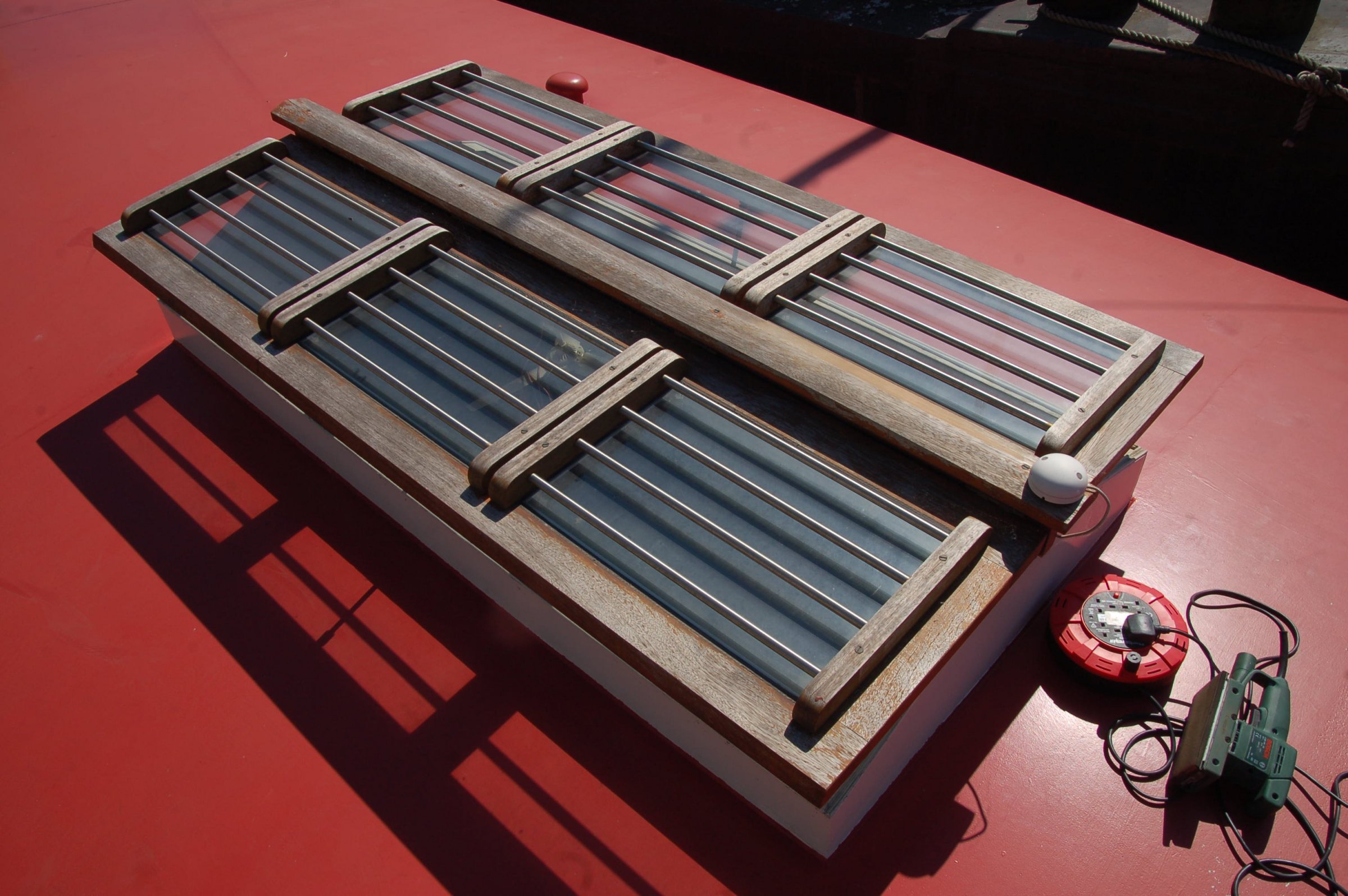

Finished refinishing the pigeon roof! Before and after: Now we just have to do the same for the whole wheelhouse... several times as much work.